How to make beer by yourself at home?

How to make beer by yourself at home?

From malt to our bottled beer, the following steps are required. Taking the 500L brewhouse system as an example, this article introduces the complete process and steps of beer brewing through the automated two vessels beer brewing system.

The main four parts of beer making is: mashing/lautering/boiling/whirlpool,for the 500L two vessels brewhouse system. Using the gas steam boiler to provide heating power, jacketed heating.

First of all, the malt needs to be pulverized into powder by a roller mill, which is conducive to better saccharification and dissolves proteins and the like into the water during the heating process.

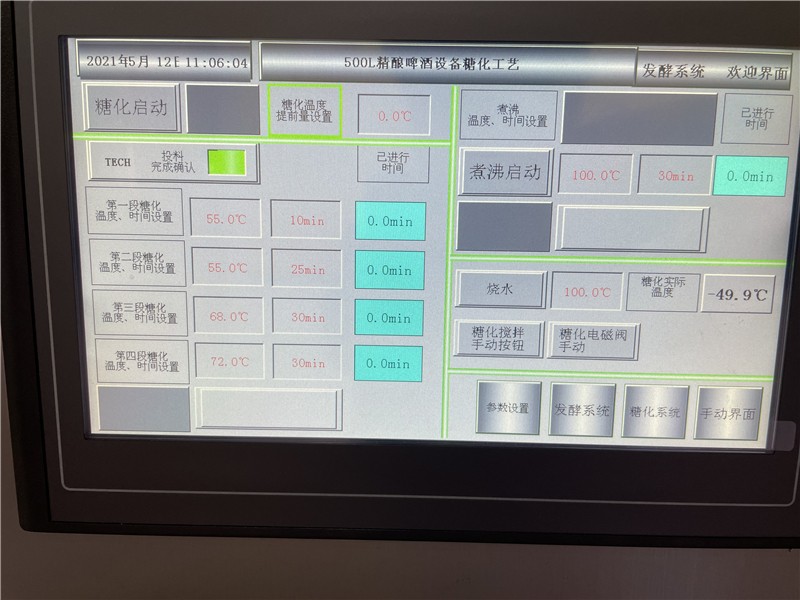

Enter the administrator password on the PLC control touch screen to enter the device user interface, open the valve to pump raw water, and after reaching a certain amount of water, close the valve and set the boiling water temperature to 70-80 degrees.Enter the administrator password on the PLC control touch screen to enter the device user interface, open the valve to pump raw water, and after reaching a certain amount of water, close the valve and set the boiling water temperature to 70-80 degrees. Set the heating time, when the temperature is reached, the system will beep.

Turn on the motor to stir in the mash tun, and the malt is saccharified in 70-80 degrees hot water. After the mashing is completed, turn on the mash pump and pump the mash into the lauter tun.

The False bottom between the lauter tun and the whirlpool tun plays a role of filtration. With a compressor, it can achieve natural filtration and suction filtration.

The filtered wort falls into the spin tank, and then through the wort pump, the wort is pumped into the mash/kettle tun for boiling.The filtered wort falls into the whirlpool tun, and then through the wort pump, the wort is pumped into the mash/kettle tun for boiling.

The system automatically heats up according to the boiling time and temperature of the equipment, and automatically shuts down after completion. During this period, hops or hop products are added for flavoring.

After the boiling, the hot wort is pumped into the whirlpool tank, and the wort is fed tangentially into the tank to form a whirlpool, and the impurities contained in it will settle. After a simple filtration, the wort mashing part is over.The whole process is about 6-8 hours

The second part is fermentation. The hot wort is pumped into the plate heat exchanger for first cooling.

Then enter the fermenter for fermentation. The fermenter is jacketed, equipped with a temperature sensor, jacketed insulation layer 80MM polyurethane, heat preservation and refrigeration, pre-embedded with cold water pipe, the chiller is fed with cold water to prepare glycol water, and stored in the cold water pipe In the middle, the cold water pump is controlled by PLC, and the cold water is circulated and refrigerated in the jacket of the fermenter.

Online monitoring of water temperature of fermentation refrigerant, traceable fermentation history.

After two weeks of wort in the fermentation tank, the fermentation is completed and the beer brewing process is completed.

The system after mashing is connected to the CIP cleaning pump, and the rotating cleaning spray ball in the tank sprays and cleans the equipment.For brewers who love live beer, after fermentation, the beer is ready to drink, and the beer fermentation tank can be used as a wine storage and sales tank. If there is a need for beer to be sold in retail, WEMAC will also equip you with filters and filling machine devices. This complete set of beer production technology and flow is over.

If you want to experience the fun of brewing and brewing personalized craft beer, WEMAC can help you. From small home brewing equipment to large-scale commercial beer brewing systems, these are our superior products.

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- Nano brewery equipment, brewing systems manufactur

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- hops addition gun

- hop additive gun

- mixing tank manufacturers

- pilot brewing system

- Craft beer making equipment for Malaysia

- CIP system

- Microbrewery machine

- professional Cleaning in place equipment

Newest Products

Marketplace home & living lifestyle home brewing d...

The home brewing and distilling market has grown in popularity in recent years, ...

More >>

Beer brewhouse and fermentation tanks microbrewery

WEMAC-Main product categories:

Craft Beer equipment,Cider making machine,Beer b...

Best plate heat exchanger for beer brewery

The WEMAC plate heat exchanger (PHE) series is extensive, including multiple typ...

More >>

Home beer brew kits brewery equipment

This skid home brewing system is designed for craft brewing amateurs who has bee...

More >>

Top quality fermenter and beer bright tank

Brite or Bright Beer Tanks are also known as Beer Conditioning Tanks or Beer Ser...

More >>

Pro two vessels 5BBL craft brewery in Michigan

Professional beer brewhouse sale well in Michigan state,turnkey brewery services...

More >>

4000L Commercial Beer Brewery Equipment

4000L four vessels craft beer brewing brewery system,gas steam heating,with a be...

More >>

500L Top quality craft beer brewery equipment

Double vessels craft beer brewing brewhouse for sale,mash/kettle tun + lauter/wh...

More >>

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle...

More >>

Best 50L home beer microbrewery equipment

Two vessels combination,mash/lauter tun+kettle/whirlpool tun brewery.electric co...

More >>

100L beer brewing home microbrewery

Mash/lauter/kettle tun+whirlpool tun,electric coil heating,two stages cooling,pl...

More >>

Build me a 1500L beer brewery

mini beer brewery machine from 50L,which is suitable to use in home and family b...

More >>