Best 50L home beer microbrewery equipment

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

50L beer brewing breweryhome beer brewing microbreweryelectric heating brewery50L home craft beer brewing fermenter

Best 50L home beer microbrewery equipment

Are you ready to take your home brewing to the next level? Look no further than our top-of-the-line 50L home beer microbrewery equipment. Crafted with precision and designed for enthusiasts who demand excellence, this equipment will transform your home into a microbrewery capable of producing high-quality beer with ease.

Brewhouse of Best 50L home beer microbrewery equipment

Mash/lauter tun+kettle/whirlpool tun.the 50L home beer microbrewery equipment are heated by inner electric element.

The mashing and fermentation of the whole set of machines are separated. The bottoms of the two bodies are equipped with universal wheels,which can be moved by hand.

Stainless steel round tube cart armrests, bottom square stainless steel tube rack, universal wheels installed at the bottom, the height of the equipment legs and top cover can be adjusted according to the height of the room in which it is used.

And The whole set of machines are all made into a quick-fit connect type,and the machine can be used without installation after it arrives at the site.The pipeline connection of the equipment is simple,water and electricity pipe,and only one wort quick-fit hose from mash to fermentation.

The electrical connection of the machine is plug and socket type, the total installed capacity is about 9.85KW, and the maximum power consumption is about 5.3KW.

Fermentation and cooling system of Best 50L home beer microbrewery equipment

The stainless steel frame welded with chiller,glycol water tank and fermenters,all in one frame,The cold water pump transports cold water to circulate cooling in the fermentation tank.

The volume of the fermentation tank is 50L, and the monthly output of 3 fermentation tanks can reach 300L.

In addition to convenient installation and operation, 50L home beer micro brewing equipment has a high fault tolerance rate. For newbies in beer brewing, small equipment can be used for experimental research. The amount of raw materials used is small,and the production cost is low. For the small water and electricity consumption,even ordinary families can afford it.

Configuration list of Best 50L home beer microbrewery equipment

Name | Component | Specification | Technical Description | Material |

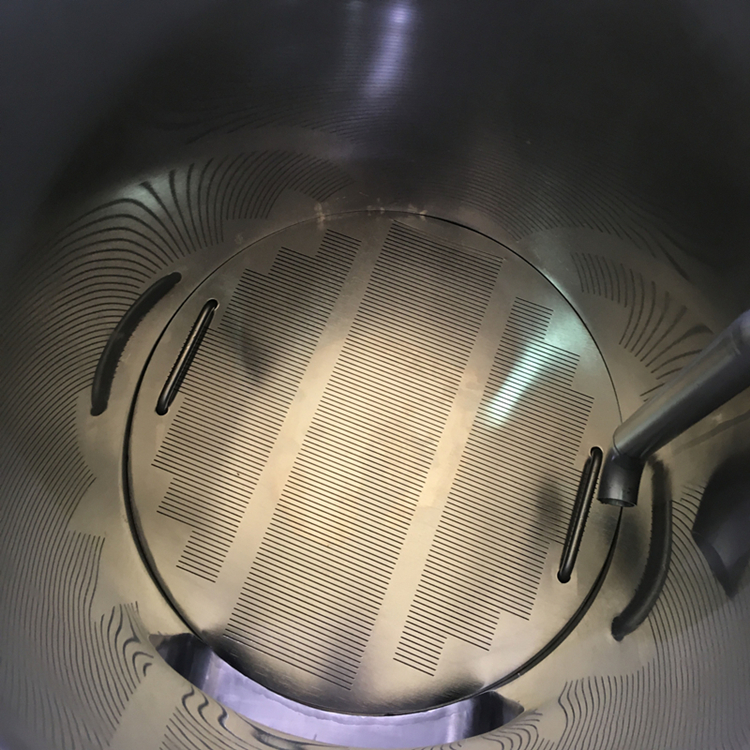

Mashing system | Mash & lauter tank | 50L | 1、Inner shell is made of SUS304,thickness is 2.5mm,Cladding thickness is 1.5mm 2、Electric heating, 1-1.5℃/min,elliptical manhole, butterfly head 3、Heat-resisting polyurethane foam is used for keeping warm,thickness is 80mm 4、Full capacity of lauter part is 60L 5、Heat-resisting polyurethane foam is used for keeping warm for lauter part,thickness is 80mm 6、Feed on the top of the filter, inlet and flush filter on the same level.The upper 2 root into the tube, one for reflow and wash the worse.Internal bad washing device adopts double umbrella flow plate form, a second washing pipe, used to wash lauter tank, washing ball confirm with ISO standard. 7、Upper lauter with oval endoscopic manhole side out of the discharging mouth;Butterfly tank bottom, lauter out main belt audition and health sampling valve, sight glasses level installation;And the suction lauter,natural lauter can realize , natural filtering can synchronize when washing. 8、Filter plate: milling.Material:SUS304, opening rate is about 10%;Surface light, smooth;Local can open, convenient cleaning, the use of deformation;Filter plate and the distance between the bottom of the pot between 2 to 5 cm, at the bottom of the tank with the cleaning device, uniform not less than three. 9、The thermometer meter is digital display.The precision of platinum thermal resistor is ±0.3℃ .The temperature range is from 1℃ to 120℃ 10、Equipped with cleaning tube, wash ball confirm with ISO standard. | SUS304 |

boiling and whirlpool tank | 50L | 1、Full capacity of is 95l,empty capacity is higher than 40%2、The inner shell is made of SUS304, thickness is 2.5mm,The cladding thickness is 1.5mm.3、Polyurethane foam is used to keep warm for the filter tank.The thickness of keeping warm material is 75mm4、Steam outlet pipeline on the top which diameter is ¢76 for the steam discharging.the steam outlet pipeline will equip with condensed water collecting device and the outlet pipeline should be embedded in the thermal insulation layer5、Counterclockwise tangential feeding when depositing, feeding port under the liquid level 1/3;With liquid level tube, with a breathing hole, side installation fast loading manhole.The bottom shape and material discharging to insure the effect of depositing as well as to improve the operation convenience, reduce the loss of material liquid.Hanging heavy discharging pipe and drainage pipe between a bypass.With cleaning tube, embedded in the thermal insulation layer.6、Inner Surface welds polishing process.The apperance is beautiful.Pipeline layout,opening meet the requirement of operation, installation and visiting.7、Whirlpool tank equipped with cleaning tube, wash ball confirm with ISO standard. | SUS304 | |

Mash support | stainless steel 304 . | SUS304 | ||

Wort pump | 1.5T/H | Sanitary centrifugal pump, pump body and impeller material stainless steel 304, conform to the requirements of the health level of pump;370 w, lift 10 ~ 15 m;Granularity for 3 to 5 mm. | SUS304 | |

Fermentation system | Fermentation tank | Effective volume50L | 1.The inner shell of tank material is SUS304, national standard thickness is 2.5 mm; cladding material is SUS304,thickness is 1.5 mm. 2.Dribbling is used to cool,material is SUS304, thickness is 1.5 mm, withstand voltage is 3 bar , cylindrical cooling temperature area is about 40% of the cylinder surface area , the cones cooling area is about 50% of the surface of the cones. 3.Polyurethane foam is used to keep warm,the thickness is 80 mm. 4.Withstand voltage of tank is 2.5bar 5.60 °hypocone is compressive strength design. 6.Empty capacity is 20%. 7.nternal roughness is less than 0.4 um , no distortion, no scratches, weld highly polishing 8.The upper installation lamp lens. 9.The tank equips with temperature sensor,sample valve,machanical valve.Discharge outlet is at the bottom, beer outlet valve is at the pyramis. 10.Discharge pipe is at the bottom ,the diameter is Ø25。 | SUS304 |

Mechanical valve | Material is SUS304, Rifeng brand | SUS304 | ||

Cooling system | Refrigerator | 1P | 1.Type: air-cooled refrigeration unit. | SUS304 |

Alcohol water tank | 50L | 1.It is made of SUS304, 2.Inner equip with copper evaporator,heat radiating area matches evaporator 3.Automatic temperature control. | SUS304 | |

Alcohol water pump | 0.8T/H | Alcohol water circulating pump, ability to meet the requirements. | ||

Electric System | PLC and touch screen control | 1. Realize special fermentation that is two warming segments, three sections of cooling ; 2. According to different beer can set different fermentation curve, to meet different fermentation technology. 3. Achieve 2-24 hours any cooling speed setting, 4. No duty for fermentation inspection 5. Temperature, time and cycle can be arbitrarily set and modified 6. System capacity meet a fermentation period.System once every 20 minutes collect data and summary,record all data of a fermentation cycle. 7. Traceability. 8. The accuracy of error is plus or minus 0.3 ℃. | SUS304 | |

switchboard | Fermentation &refrigeration shared one, mashing use the other | SUS304 | ||

Fermentation control solenoid valve | 3/4” | Stainless steel spring, fluorine rubber diaphragm, DC24V. | SUS304 | |

Wire and Cable | Signal lines use the shielded wire | SUS304 | ||

threading pipe | 1.Stainless steel decoration pipe,the size & number meet site installation requirements. | SUS304 | ||

Pipeline fittings | Mash line | Φ32 | Including the sugar barrels, saccharifying all valves and piping.Valve shows that manufacturers, including water pipe. | SUS304 |

The alcohol water line | Φ32 | Option 1: one solenoid valve, two ball valve, pipe filters, pipe insulation thickness is 3 cm, outsourcing stainless steel decoration pipe. | SUS304 | |

Φ20 | Option 2: use one solenoid valve, use PPR pipe, 3 cm rubber sponge to keep wartm, outsourcing aluminum foil paper. | PPR | ||

saccharimeter | 0-10,10-20 |

FAQ

1. What is a 50L home beer microbrewery equipment?

A 50L home beer microbrewery equipment is a complete brewing system designed for homebrewers who want to produce high-quality beer in smaller batches, typically 50 liters (approximately 13 gallons) at a time.

2. What is included in a 50L home beer microbrewery equipment package?

Typically, a 50L microbrewery equipment package includes essential components such as a fermenter, brewing kettle, temperature control system, fermenting vessels, and often, a mash tun. The specific components may vary based on the manufacturer and customization options.

3. Is this equipment suitable for beginners?

Yes, many 50L microbrewery equipment kits are designed to be user-friendly and are suitable for beginners. They often come with step-by-step instructions to help newcomers get started with home brewing.

4. Can I brew different styles of beer with this equipment?

Absolutely! The 50L capacity allows you to brew a wide range of beer styles, from ales and lagers to specialty and experimental brews. It provides the flexibility to explore and experiment with various recipes.

5. How does temperature control work in this equipment?

Temperature control is essential in brewing to achieve consistent results. Many 50L microbrewery systems come with built-in temperature control systems or options for attaching external temperature control devices to maintain precise brewing temperatures.

6. Can I expand this equipment for larger batches in the future?

Depending on the manufacturer, some 50L microbrewery equipment may offer expansion options. You can explore add-ons or larger fermenters if you decide to scale up your brewing capacity.

7. Is it easy to clean and maintain?

Proper cleaning and maintenance are essential for brewing equipment. Many systems are designed for easy cleaning and maintenance, with removable components and materials that resist corrosion.

8. Are there any safety considerations when using this equipment?

Safety is paramount when brewing at home. Users should be familiar with the equipment, follow safety guidelines, and exercise caution when working with hot liquids and pressurized vessels.

9. What resources are available for troubleshooting and support?

Many manufacturers and homebrewing communities offer resources for troubleshooting and support. You can find online forums, guides, and communities of homebrewers who are willing to share their expertise.

10. Can I personalize my brews with this equipment?

Yes, one of the joys of home brewing is the ability to personalize your brews. You can experiment with different ingredients, hops, malts, and brewing techniques to create unique and customized beer flavors.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- complete brewery for sale

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- hops addition gun

- mixing tank manufacturers

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- CIP system

- Microbrewery machine

- professional Cleaning in place equipment

FEATURED PRODUCTS

Best 50L home beer microbrewery equipment

Two vessels combination,mash/lauter tun+kettle/whirlpool tun brewery.electric coil heating,the mashing system is made of...

More >>

100L WEAMC high quality Customized home brewing microbrewery/pilot beer equipment system

①Malt crusher

②Mash system

③Fermentation system

④cooling system

⑤Water treatment system

⑥ Cleaning equipment

⑦Con...

Chinese manufacturer made 50L Home beer microbrewery equipment hot sell in mini bar

The complete set of 50L home beer brewing equipment composes the following parts:

1.Mashing system,mash&lauter tank,boi...

30L Home microbrewery beer brewing equipment hot sell in England ZZ

Home Craft beer mashing machine,experience the fun of brewing beer, brew a safe, reliable, preservative-free beer of you...

More >>

30L Hot sell in America stainless steel small size home microbrewery equipment ZZ

Small home-brewed beer equipment, made of high-quality stainless steel, integrates functions such as mash and boiling, h...

More >>

Home craft beer brewing equipment Chinese supplier

Home brewing equipment refers to home brewing equipment. The volume and output of this kind of equipment are very small....

More >>

China 30l and 50l professional home microbrewery brewing equipment supplier

Family beer brewing system usually refers to micro brewing equipment specially used in family or small restaurants, brew...

More >>

50L home microbrewery for sale in Canada WEMAC G029

We also meet with experts and professionals to discuss beer producing equipment of different kinds and popularity in bee...

More >>