4000L Five vessels turnkey beer brewery

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

4000L Five vessels turnkey beer brewery

Craft beer has flourished in the past few years and is favored by more and more consumers. With the increase of market demand, more and more breweries and entrepreneurs seek opportunities for large-scale production. The 4000L five-system one-stop craft beer brewing equipment has become an ideal choice to meet this demand. This article describes the device and its benefits.

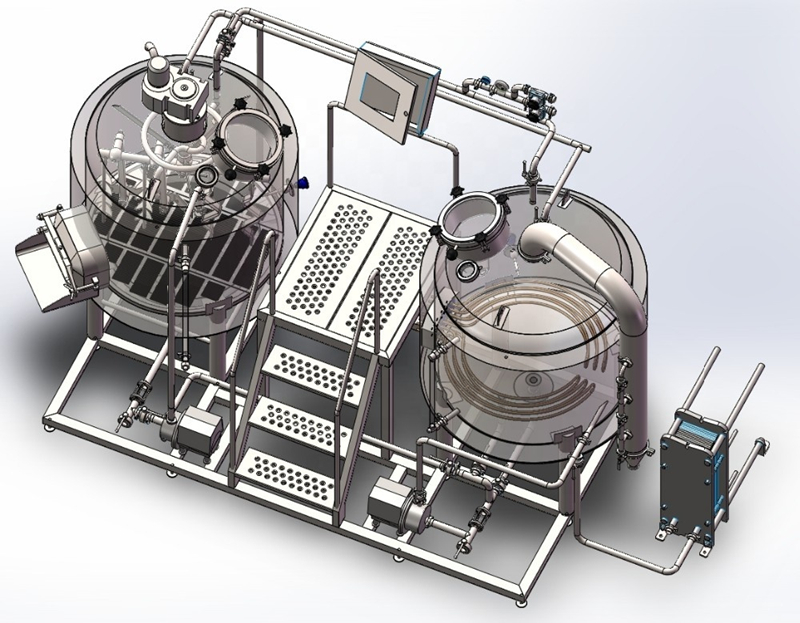

Combination of Complete set of 4000L Five vessels turnkey beer brewery

The brewery can be SUS304 or copper cladding in material, steam, electric or direct fire heating,two/three or five vessels brewhouse.

The system contains milling,brewhouse, fermenter,bright beer tank, control unit,Glycol cooling Unit and CIP Cleaning System,as well as kegging and Bottling system.

The mashing process and the wort filtration process are completed by Mash tun/ lauter tank;The boiling and whirlpool processes are completed by one tank.

This system usually brews two or three batches a day.According to different fermentation cycles of brewed beer,6pcs double batches fermenters or 12pcs single batch fermentors can usually be configured.

The system also needs to be equipped with a complete automatic or manual control system,malt milling system,CIP system, cooling system,steam heating system,air system, etc.

Features of Complete set of 4000L Five vessels turnkey beer brewery

Double mash tun +double kettle tun+whirlpool tun,without lauter tun.using the filter press machine to replace the lauter tun,

The use of filter press has high production efficiency and can reach more than 12 batches per day;reduces labor intensity,and can realize automatic control of filtration,system CIP and filter cloth cleaning;after the original wort filtration is completed,the membrane blows and squeezes the grain layer,Without using the lees water,80% of the extract in the lees layer can be recovered and the lees layer becomes thinner at the same time, which improves the efficiency of lees washing and reduces the wheat husk polyphenols,pigments,bitter substances and malt that affect the flavor of beer.The high molecular weight protein, fat,fatty acid and β-glucan in the wort enter the wort to ensure the good taste and high brightness of the wort;

Low investment, quick results,high equipment utilization and small floor space.The requirement for the main material malt is not high,the raw material crushing rate is relatively fine,the yield of extract is improved,the relative amount of auxiliary materials is increased,and the production cost is reduced.

Heating system of 4000L Five vessels turnkey beer brewery

Heating system of made up of gas steam boiler,The filtered demineralized water enters the boiler,and the gas produces the steam needed for beer mashing/boiling.

The top of the brewing system is equipped with a condensation recovery pipeline to realize the recycling and reuse of indoor steam,improve utilization,reduce production and operation costs,and reduce indoor environmental pollution.

According to the energy supply situation at the customer's site, we can provide a variety of boilers such as electric heating and direct fire heating.

Fermentation system of 4000L Five vessels turnkey beer brewery

4000L conical cooling jacketed fermenters in Client's site.The volume of the fermentation tank is designed according to the working capacity of the mash system.With a 4000L brewing system,according to the production capacity of at least 8 batches per day,the daily output of craft beer can reach 32000L-40000L.

Miller board jacket refrigeration, polyurethane foam insulation layer. The material is thick, the thickness of the inner plate is 3mm, and the thickness of the outer plate is 2mm. It has a high degree of pressure resistance and can be used in commercial beer brewing plants for more than 30 years.

The fermentation tank is equipped with a side sampling valve for aseptic sampling. The top of the tank is equipped with a CIP cleaning ball, rotating cleaning, and a bottom discharge port.

4000L capacity brewing equipment has the following detailed advantages

Large production scale: The capacity of 4000L means that each batch can produce a large amount of beer, which is very important for commercial breweries or brewing enterprises that require large-scale production. Large-capacity equipment can meet market demand and provide more product offerings to meet growing consumer demand.

High efficiency: Compared with equipment with smaller capacity, the capacity of 4000L can improve the brewing efficiency. Each batch produces more beer, reducing frequent operations such as refueling and cleaning, saving time and labor costs. This helps to speed up the production cycle and make the brewing process more efficient.

Quality Assurance: Large-capacity production helps maintain the stability of beer quality. Consistency is an important feature of craft beer, ensuring that each batch of beer is consistent in taste, flavor and quality, and can win the trust and love of consumers. The capacity of 4000L enables winemakers to better control the brewing process and ensure product stability and quality.

Market competitiveness: With the increasingly fierce competition in the craft beer market, brewing equipment with a capacity of 4000L makes the brewery more competitive in the market. Large-capacity equipment can meet more orders and needs, which is conducive to expanding market share, increasing sales and income.

Adapt to diverse needs: The equipment with a capacity of 4000L allows winemakers to flexibly respond to diverse needs. They can produce more types of beer to meet the tastes and preferences of different consumer groups. At the same time, brewers can also carry out more innovations and experiments, and develop more beer products with unique flavors.

The selection of brewing equipment with a capacity of 4000L is to meet the needs of large-scale production, improve brewing efficiency, maintain quality stability, and maintain competitiveness in the fiercely competitive market. Such equipment provides brewing companies with more opportunities and flexibility, and promotes the continuous development of the craft beer industry.

We provide customers with on-site installation and commissioning work, and provide training and guidance on the use of equipment. If you are interested in this 4000L five vessels beer brewing system, please contact us.

FAQ

What is a 4000L Five Vessels Turnkey Beer Brewery?

A 4000L Five Vessels Turnkey Beer Brewery is a complete brewing system capable of producing up to 4000 liters (4,000 liters) of beer per batch. It consists of five essential vessels: Mash Tun, Lauter Tun, Brew Kettle, Whirlpool, and Hot Liquor Tank. These vessels work together to facilitate the entire brewing process, from mashing and lautering to boiling, whirlpooling, and fermentation.

What does "Turnkey" mean in the context of this brewery?

"Turnkey" means that the brewery comes fully equipped and ready for operation upon delivery. It includes all the necessary equipment, controls, and accessories needed for brewing beer without requiring any additional purchases or installations.

What are the advantages of a 4000L capacity brewery?

A 4000L capacity brewery offers several advantages:

High production volume: With a large capacity, you can brew substantial batches of beer, making it suitable for commercial breweries and large-scale operations.

Efficiency: The larger vessel size allows for efficient brewing and reduced production time, as you can produce more beer in each batch.

Consistency: The consistent batch size ensures uniformity in taste and quality across different production runs.

What is the typical setup of a 4000L Five Vessels Brewery?

The typical setup includes the following five vessels:

Mash Tun: Used for mashing, converting starches into fermentable sugars.

Lauter Tun: Used for separating the liquid wort from the solid grain after mashing.

Brew Kettle: Used for boiling the wort with hops, creating bitterness, flavor, and aroma.

Whirlpool: Used to separate the hop and protein particles from the boiled wort.

Hot Liquor Tank: Used for holding and heating water for various brewing stages.

Is the 4000L brewery suitable for small craft breweries?

A 4000L brewery might be too large for small craft breweries or startups, as it requires a significant initial investment and larger space. Smaller craft breweries typically opt for breweries with lower capacities, such as 500L, 1000L, or 2000L, depending on their production needs.

What additional equipment is required for the brewery to be fully operational?

Apart from the five vessels, the brewery might require various additional equipment and accessories, such as fermentation tanks, cooling systems, yeast propagation equipment, filtration systems, packaging equipment, and a control system to manage the brewing process effectively.

What are the maintenance requirements for a 4000L Five Vessels Brewery?

Maintenance requirements include regular cleaning, sanitization, and inspection of all vessels and associated equipment. Preventive maintenance should be conducted to ensure the brewery operates efficiently and to prevent breakdowns.

Can the brewery produce different types of beer?

Yes, the brewery can produce a wide range of beer styles, as it allows the brewmaster to control the brewing process and experiment with different ingredients, mashing profiles, hop additions, and fermentation conditions.

How long does it take to brew a batch of beer with this brewery?

The time required to brew a batch of beer depends on the recipe and the specific brewing process. Generally, it takes several hours for mashing, boiling, and cooling, followed by a fermentation period that can last from a few days to several weeks, depending on the type of beer being produced.

What kind of technical support and warranty are provided with the brewery?

The specific technical support and warranty details may vary depending on the manufacturer or supplier of the brewery. Generally, reputable suppliers offer technical support for installation, training, and troubleshooting. Warranties typically cover defects in materials and workmanship for a specific period, ensuring peace of mind for the buyer.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- Nano brewery equipment, brewing systems manufactur

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- hops addition gun

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- hop additive gun

- pilot brewing system

- CIP system

- Microbrewery machine

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Turnkey brewing equipment supply near me

Turnkey brewing equipment supply-WEMAC can supply turnkey brewing equipment system.We are one of the most excellent turn...

More >>294.jpg)

All in one brewing system Australia

WEMAC beer equipment manufacturer is a well-known all in one brewing system, with more than 60 years of experience in th...

More >>

10HL 1000L Romania turnkey beer brewery equipment ZXF

1000L electric steam heating beer brewing brewhouse,sell well in Romania.Personalized customization, a variety of heatin...

More >>

Stainless steel boiling tank beer brewing brewery turnkey system supplier ZXF

All size brewery for sale,WEMAC Provide turnkey service for beer brewing system,Professional brewers and technical engin...

More >>

WEMAC 3000L Turnkey beer brewing brewery foul vessels brewhouse manufacturer ZXF

WEMAC specializes in undertaking large, medium and small beer brewing turnkey projects, the quality of WEMAC meets the G...

More >>

Modern beer making brewery turnkey brewhouse system made of high quality stainless steel ZXF

WEMAC provides a turnkey system for a modern beer brewing factory. From the storage and crushing of raw materials and ma...

More >>

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

Grain Handling

Heating System - Electric, Steam, or Direct Fire

Brew House Tanks

Brew House Controls

Pumps

Glycol &...