Professional beer brewing equipment for sale WEMAC H002

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

Professional beer brewing equipmentprofessional brewing equipmentProfessional brewing equipment for saleProfessional brewing equipment for sale

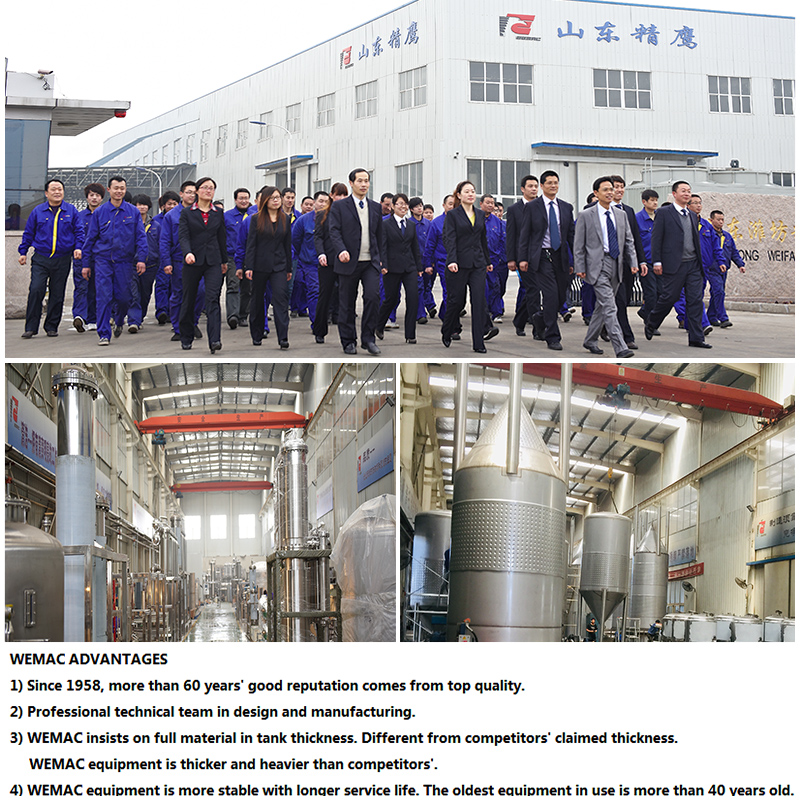

In the ever-evolving landscape of the craft beer industry, where passion for flavor and innovation meets precision craftsmanship, owning professional brewing equipment is a dream come true for many aspiring brewers and established breweries alike. WEMAC, a reputable name in the field, offers a comprehensive range of professional beer brewing equipment that caters to the diverse needs of the modern brewing community. Today, let's delve into the world of WEMAC professional brewing equipment and why it's a smart investment for anyone serious about crafting exceptional brews.

Introduction to WEMAC: Craftsmanship Meets Efficiency

WEMAC has long been synonymous with quality, durability, and innovation in the world of professional beer brewing. Our equipment is designed and manufactured with the utmost attention to detail, ensuring that every batch of beer produced meets the highest standards of taste and consistency. Whether you're a hobbyist looking to upgrade your home brewing setup or a commercial brewery seeking to expand its production capacity, WEMAC has something to offer.

Professional beer brewing equipment for sale

Smash system is used for smashing relevant material to meet process requirement. It is composed of smashing machine, material case, powder case, conveying devices and other devices. There are two smashing types. That is dry smashing and wet smashing systems. Both are roller smashing machine special designed for craft beer production. The machine is with small size, easy to move, fast installation, simple operation, fast smashing ratio, fast filtering speed. Wet smashing method is usually used in big beer brewing plant. While small craft beer brewery equipment normally adjust dry smashing method. Small millstone smashing machine is also a good choice for small beer brewery production. WEMAC smash system is with low cost, small size and easy operation needed.

Mash system and brewhouse system is the professional equipment for mash, filter, boiling and sediment according to process requirement. The system is mainly composed of mash tun, boiler, filter slot, sediment slot, storage slot, brewery water tank, hot water tank, spent grain buffer tand, negative pressure distillation energy saving system, heat exchanger, energy recovery system and other relevant devices. Big craft beer brewery plant mainly adjusts 4 unit and 5 unit composition of mash system for beer production. 2 unit and 3 unit smash system composition is usually for micro beer brewing equipment. The inner layer of smash system adopts 304 and 316 stainless steel as manufacturing material, that is stable with long lifetime. Outer surface adjust stainless 304 or copper and other relevant material with good appearance. Heat insulation layer adjusts special rock wool to preserve heat energy efficiently. The big area dimple plate makes sure enough evaporation in beer brewing process. WEMAC smash system is the most stable and efficient equipment in beer brewery production.

Fermentation system is composed of beer fermenter and relevant devices, including fermenter, yeast propagation equipment, yeast feeding keg and so on. Beer fermenter is divided into 2 styles, that is horizontal fermenter and vertical fermentation tank. Cleaning and sterilizing system is need in beer production process to ensure beer production system reach sanitation standard. It is mainly composed of alkaline water tank, acid tank, hot water tank, sterile water tank, sterilization tank, pump and other devices. Cooling system is composed of ice water tank, cool water tank, fast cooling device, unit cooler and relevant devices. It can keep proper temperature for beer production process. Electric control system normally adjust PLC control and touch screen to meet different customers’ request. Material distribution system is pumps and pipes needed in beer brewery equipment. It is the most important assisting equipment.

WEMAC provides complete beer brewing equipment in the whole beer production process.

Key Features of WEMAC Professional Brewing Equipment

Versatility and Scalability: WEMAC's equipment is designed to grow with your brewing needs. From small-scale, all-in-one brewing systems perfect for home or microbreweries, to large-capacity commercial setups capable of producing thousands of liters per batch, there's a solution for every size and stage of your brewing journey.

High-Quality Materials: Durable materials like stainless steel are used throughout WEMAC's brewing equipment, ensuring long-lasting performance and resistance to corrosion. This not only enhances the lifespan of the equipment but also ensures that your beer remains pure and uncontaminated throughout the brewing process.

Advanced Technology: Incorporating the latest brewing technology, WEMAC equipment offers precise temperature control, automated fermentation monitoring, and efficient heat recovery systems. These features allow brewers to fine-tune their recipes, optimize fermentation conditions, and reduce energy consumption, resulting in better-tasting beer and a more sustainable brewing process.

Easy Maintenance and Cleaning: Recognizing the importance of hygiene in beer brewing, WEMAC designs its equipment with easy access points and smooth surfaces that facilitate thorough cleaning and maintenance. This helps maintain the integrity of your beer and ensures that your equipment remains in optimal working condition.

Comprehensive Support: Buying WEMAC equipment means gaining access to a team of knowledgeable and dedicated customer support specialists. Whether you need assistance with installation, troubleshooting, or upgrading your setup, WEMAC is there to provide personalized guidance and solutions.

Why Invest in WEMAC Professional Brewing Equipment?

Investing in WEMAC professional brewing equipment is a strategic move for anyone looking to elevate their brewing game. With its focus on quality, versatility, and technological advancements, WEMAC equipment enables brewers to produce high-quality beer consistently, while also reducing operational costs and enhancing overall efficiency. Moreover, the brand's commitment to customer support ensures that you'll have the resources you need to succeed every step of the way.

In conclusion, WEMAC professional beer brewing equipment represents the pinnacle of craftsmanship and innovation in the brewing industry. Whether you're a seasoned pro or just starting out, investing in WEMAC equipment is a smart decision that will set you on the path to crafting exceptional beers that delight the palates of discerning beer lovers worldwide. With a range of options to suit every need and budget, WEMAC truly has something for everyone in the world of craft beer.

FAQ

Q: What sets WEMAC apart from other brewing equipment manufacturers?

A: WEMAC stands out for its commitment to quality, durability, and innovation. Our equipment is crafted using high-grade materials like stainless steel, ensuring long-lasting performance and resistance to corrosion. We incorporate the latest brewing technology into our designs, offering precise temperature control, automated fermentation monitoring, and energy-efficient features. Additionally, our team provides comprehensive support to our customers, from installation to troubleshooting and upgrades.

Q: Are WEMAC brewing systems suitable for both home and commercial use?

A: Yes, WEMAC offers a wide range of brewing equipment that caters to both home brewers and commercial breweries. Our all-in-one systems are ideal for hobbyists and small-scale operations, while our larger commercial setups are designed to meet the demands of high-volume production.

Q: Can I customize my WEMAC brewing equipment to suit my specific needs?

A: Absolutely! WEMAC recognizes that every brewer has unique requirements. We offer customization options to ensure that your brewing system aligns perfectly with your production goals, space constraints, and personal preferences.

Q: How does WEMAC ensure the hygiene and sanitation of its brewing equipment?

A: Hygiene is paramount in beer brewing. WEMAC designs its equipment with easy access points and smooth surfaces that facilitate thorough cleaning and maintenance. Our systems are also made from materials that are resistant to corrosion and contamination, further ensuring the purity and safety of your beer.

Q: What kind of after-sales support does WEMAC provide?

A: WEMAC is dedicated to providing exceptional customer service throughout the entire ownership experience. Our team of knowledgeable specialists is available to assist you with installation, operation, maintenance, and any other questions or concerns you may have. We also offer spare parts and upgrades to keep your brewing system running smoothly for years to come.

Q: How does WEMAC's energy-efficient technology benefit brewers?

A: WEMAC's energy-efficient technology helps brewers reduce their operational costs by minimizing energy consumption during the brewing process. Features like heat recovery systems and optimized insulation ensure that your brewing system is as efficient as possible, allowing you to focus on crafting exceptional beer without worrying about your energy bills.

Q: Can I finance my purchase of WEMAC brewing equipment?

A: While financing options may vary depending on your location and chosen retailer, many customers find that financing their WEMAC brewing equipment is a convenient way to spread the cost of their investment over time. We recommend speaking with your local dealer or financial institution to explore available financing options.

Q: What training or resources does WEMAC offer to help new brewers get started?

A: WEMAC understands that brewing can be a complex and rewarding endeavor. To help new brewers get started, we offer a range of resources including user manuals, online tutorials, and access to our expert customer support team. We also recommend attending brewing workshops, classes, or joining online communities to further develop your skills and connect with fellow brewers.

Send a Message

If you want to ask anything just fill in the form below and send us.

Name: Horace time:2020-04-07 15:11:35

Simple and easy to use, the quality is very good, it is highly recommended.

Name: Hugh time:2020-04-03 10:47:53

Very good, very good, very very good, very easy to use. The WEMAC is very responsible.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- brewing equipment manufacturers uk,home brewing eq

- sovereign stainless steel fermenter

- home brewing distillation equipment

- Nano brewery equipment, brewing systems manufactur

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hops addition gun

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- Microbrewery machine

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

Best 500L beer brewing equipment suppliers near me

The nearest brewery system suppliers-WEMAC,we supply beer brewing system with turn-key project.

provide beer equipment ...

Beer brewing equipment for bar

The beer brewing equipment for bar can be customized to produce.Beer brewing equipment for bar can be customized design,...

More >>856.png)

Beer brewing equipment supplier a whole of brewery system US

Professional manufacturer of beer brewery equipment,more than 60 years brewery production experience.Beer equipment incl...

More >>

WEMAC Beer brewing equipment micro brewery 100L 200L 300L 500L 1000L 2000L per batch ZXF

A typical two-vessel

Combination Mash Lauter Tuns are the first combination vessel in these smaller brewhouses line ups...

WEMAC 500L two vessel three bodies mash tank of beer brewery equipment ZXY

WEMAC 500L two vessel three bodies mash tank of beer brewery equipment can mash up to 500L at a time. If it is equipped ...

More >>

WEMAC 1000L 2 vessels beer brewing system brewery equipment made of stainless steel ZXY

WEMAC 2 container beer brewing system is made of high-quality stainless steel, 316L or copper outsourcing material, whic...

More >>

100L Stainless steel mash tank of making beer machine in Australia ZXY

The 100L Stainless steel mash tank of making beer machine is used in the mash process of brewing beer. It can mash up to...

More >>

SUS304 Beer brewing machine brewery equipment widely used in mini bar ZZ

we are the professional beer brewing equipment manufacturer and supplier,we are also the pharmaceutical equipment manufa...

More >>