Three-vessels false bottom beer making brewing brewery equipment brewhouse system supplies ZXF

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

beer brewing systemThree vessels beer making breweryflase bottom brewhousethree-vessels beer making system supplies

WEMAC Beer brewing system with various kinds of system,we can design it according to production requirement.

As a supplier established in 1958, we understand the various demands of customers and provide customers with turnkey beer brewing systems and large, medium and small beer solutions.

Brewhouse

Whether in stainless steel or copper design – as the centrepiece of your pub brewery a WEMAC brewhouse is more than impressive. And the technical values are just as convincing: with a capacity up to 20 hl the pub brewhouse is suitable for all standard mashing processes and we have been using space-saving, maintenance-friendly valve clusters for 15 years now. An efficient boiling system, a spacious whirlpool and ergonomic operating sequences perfect the brewing process and guarantee best beer quality.

Wort sample testing station

WEMAC starts from the details of the system, and the design process of all products is participated by professional winemakers to ensure that the end user will not cause more troubles due to equipment problems during use.

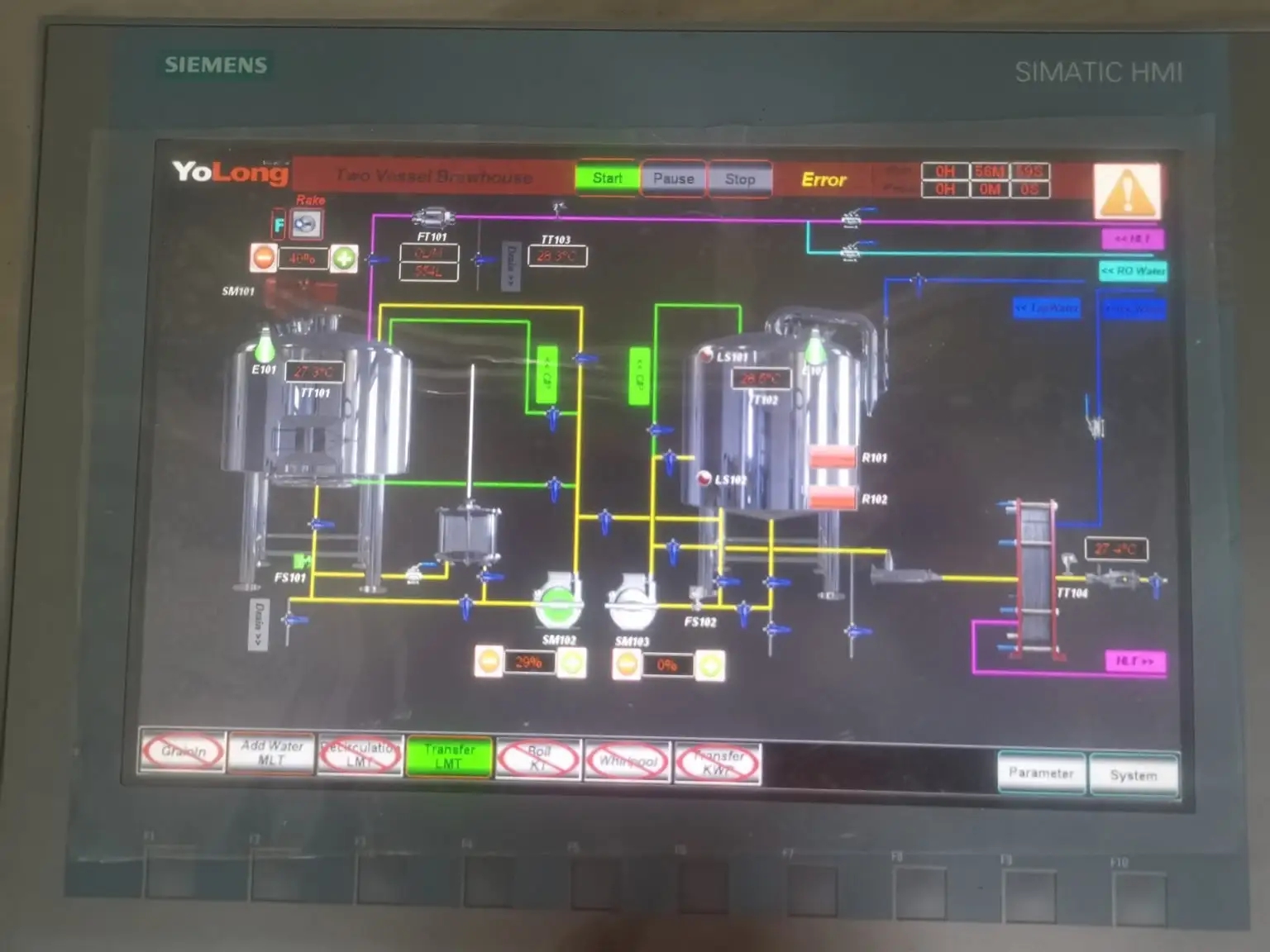

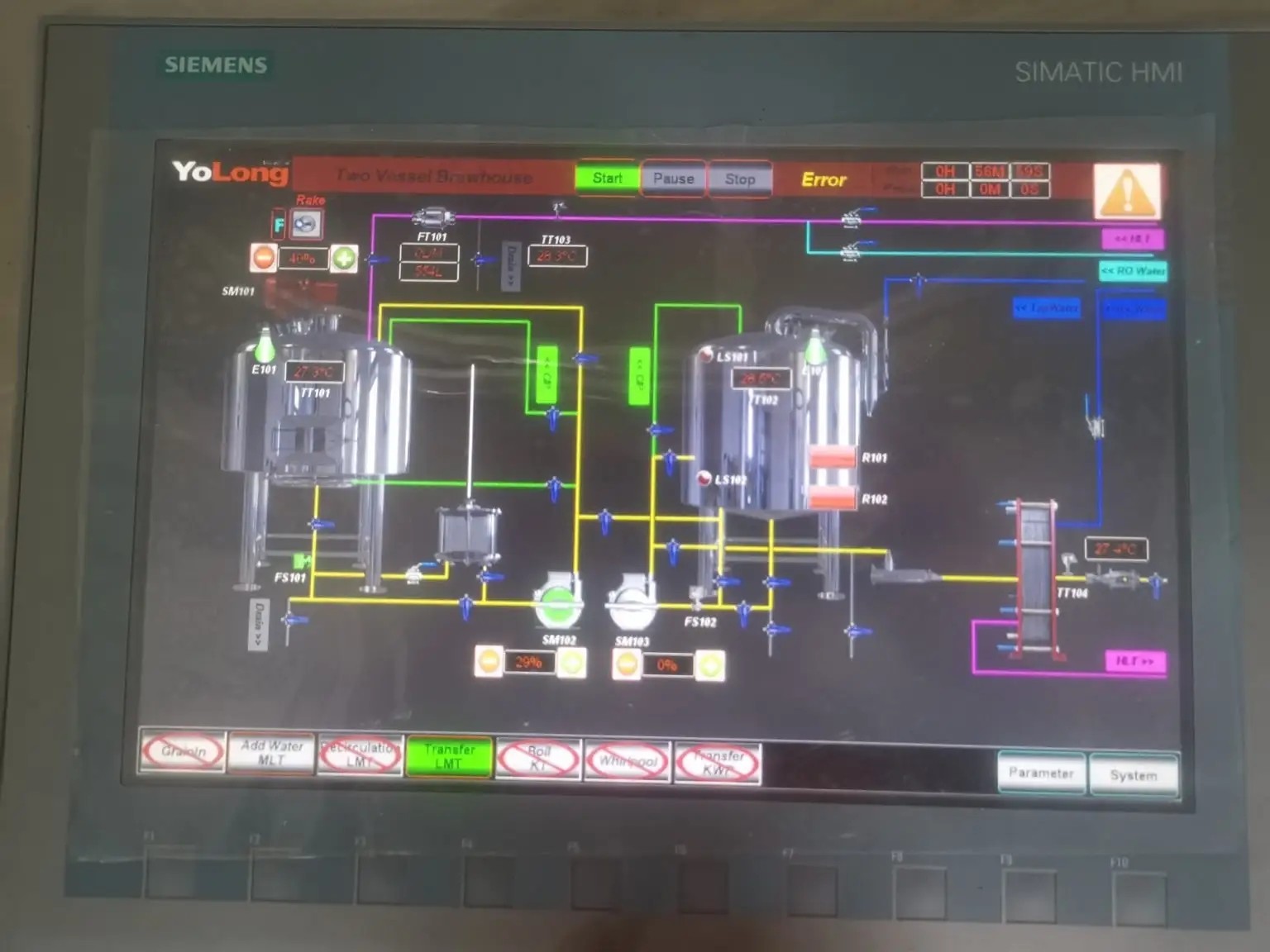

Automatic

Top brewing quality and optimum utilisation of human resources – that is what you can expect from the WEMAC automatic control. Our control is based on the Siemens programmable logic controller (PLC) and guarantees extremely simple operation. Display and operation are effected via a touch screen. Of course, this system also includes: the necessary sensors, a manual emergency operating level and software/hardware for remote maintenance plus the option of control via a tablet PC or smartphone.

Reliable operation, absolute hygiene, optimum utilisation of human resources, maximum output – all parts of a WEMAC industrial brewery are perfectly aligned in order to meet these requirements. We fulfil our demands on quality by means of meticulous construction and the use of high-quality components from well-known German manufacturers. This is also the reason each WEMAC brewery is awarded certificate.

If you are a senior beerbrewer and are interested in equipment distribution, we hope to hear from you. We have numerous case breweries at home and abroad for you to visit.

FAQ

1. What is a three-vessels false bottom beer making brewing brewery equipment brewhouse system, and how does it work?

A three-vessels brewing system typically consists of a mash tun, lauter tun, and kettle. The false bottom is a component in the lauter tun that acts as a filter to separate the liquid wort from the solid grain material during the mashing process. The system allows for precise control over the brewing process.

2. What are the main components included in a three-vessels brewing system?

A typical three-vessels brewing system includes a mash tun (for mashing), a lauter tun (for lautering and sparging), a kettle (for boiling), hot liquor tank (for hot water), pumps, and a control system. The false bottom is part of the lauter tun.

3. How does the false bottom work in the lauter tun?

The false bottom is a perforated plate or screen located at the bottom of the lauter tun. During lautering, the grain bed rests on top of the false bottom. As hot water (liquor) is sprayed over the grain bed, it filters through the false bottom, separating the liquid wort from the grain husks and solids. This process ensures a clear and clean wort for boiling.

4. What types of beer can I brew with a three-vessels brewing system?

You can brew a wide range of beer styles, including ales, lagers, stouts, IPAs, and specialty beers, using a three-vessels brewing system. The equipment's flexibility allows for various brewing techniques and recipe experimentation.

5. Is a three-vessels brewing system suitable for both small and large breweries?

Three-vessels brewing systems are versatile and can be designed to accommodate different batch sizes, making them suitable for both small craft breweries and larger commercial breweries.

6. Can I customize a three-vessels brewing system to fit my specific brewing needs?

Yes, we offer customization options for three-vessels brewing systems. You can tailor the system to match your specific brewing style, batch sizes, and requirements.

7. What kind of maintenance and cleaning are required for a three-vessels brewing system?

Regular maintenance and cleaning are essential to ensure the longevity and efficiency of your brewing equipment. This includes cleaning tanks, inspecting valves and pumps, and addressing any wear and tear.

8. How long does it take to brew a batch with a three-vessels brewing system?

The brewing time for a batch can vary depending on the recipe and process, but it typically takes several hours to complete the brewing process. Fermentation and conditioning times will add to the overall production timeline.

9. Can I expand my brewing capacity with a three-vessels brewing system in the future?

Many breweries choose to expand their brewing capacity by adding additional tanks and fermenters as their business grows. A three-vessels brewing system can be part of a scalable brewing operation.

10. What are the advantages of using a three-vessels brewing system with a false bottom?

- Advantages include precise temperature and process control, the ability to brew a wide variety of beer styles, and efficient lautering and separation of wort from grain solids, resulting in clear and high-quality wort.

When considering a three-vessels brewing system with a false bottom for your brewery, it's essential to conduct a thorough assessment of your production goals, available space, and budget. Consulting with experienced brewers and equipment providers can help you make an informed decision to support your brewing venture effectively.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- Nano brewery equipment, brewing systems manufactur

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hops addition gun

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- CIP system

- Microbrewery machine

- professional Cleaning in place equipment

FEATURED PRODUCTS

Best plate heat exchanger for beer brewery

The WEMAC plate heat exchanger (PHE) series is extensive, including multiple types of heat exchangers, suitable for all ...

More >>

500L Top quality craft beer brewery equipment

Double vessels craft beer brewing brewhouse for sale,mash/kettle tun + lauter/whirlpool tun are all made of high quality...

More >>

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Build me a 1500L beer brewery

mini beer brewery machine from 50L,which is suitable to use in home and family brewing,and micro beer brewery machine fr...

More >>

Best 500L beer brewing equipment suppliers near me

The nearest brewery system suppliers-WEMAC,we supply beer brewing system with turn-key project.

provide beer equipment ...

Best 500L beer brewhouse brewpub equipment

10hL steam heating Brewkit,most popular for the home brewing and small scale commercial brewery / brewpub.

Firstly,it c...

500L Steam heating beer brewery system Chinese suppliers ZXF

500L steam jacketed heating brewhouse,mash/kettle tun and lauter/whirlpool tun combination,PLC automaticlly control,suit...

More >>

beer brewing equipment manufacturers

Which is the best beer equipment manufacturer? How much investment does beer equipment need? What is included in the bee...

More >>