Best 500L beer brewhouse brewpub equipment

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

beer brewing equipment500L beer brewhousebeer brewhouse equipmentprice of beer brewhouse equipment

Best 500L beer brewhouse brewpub equipment

Configuration of Best 500L 5HL 5BBl Beer brewhouse brewpub equipment

Note: 1hl=100liter; 1Gallon=3.7854liter; 1BBL(Barrel ) =117Liter

500L Brewpub Beer Brewing Systems technology configuration

No. | Name | Composition | Specification | Technical parameter |

1 | Milling System | Malt Miller | 150kg/H | Double roller |

Carbon steel spray paint/Stainless steel | ||||

Power:0.75Kw | ||||

2 | Mash system | Mash/Kettle Tun | 500L | Material:SUS316L/SUS304/copper |

Interior Shell: 2B/mirror plate; TH=3mm | ||||

Dimple, coil jacketed for steam heating,electric | ||||

ABB stirring motor | ||||

80mm rock wool for insulation | ||||

Round glass manhole, dish head,with temperature | ||||

Lauter/Whirlpool Tun | 500L | Material:SUS316L/ SUS304/copper | ||

Interior Shell: 2B/mirror plate; TH=3mm | ||||

80mm rock wool for insulation | ||||

Lauter tun with round glass manhole,side mounted grain outdoor with spent grain chute,sampling valve,sight glass | ||||

Lauter plate: milling | ||||

Racking device,positive turn cultivating spent grain,reverse discharging spent grain | ||||

Tangential whirlpool inlet | ||||

With cleaning tube, with standard washing ball,cleaning pipeline ISO32 | ||||

Hot liquid tank | 1000L | Material:SUS316L, SUS304,copper | ||

Interior Shell: 2B/mirror plate; TH=3mm | ||||

80mm rock wool for insulation | ||||

Top dish head, bottom conical head, round glass manhole | ||||

Dimple, coil jacketed for steam heating,electric heating tube, combustion chamber | ||||

With a cleaning tube, with a standard wash ball, cleaning pipeline ISO32, overflow port,temperature sensor | ||||

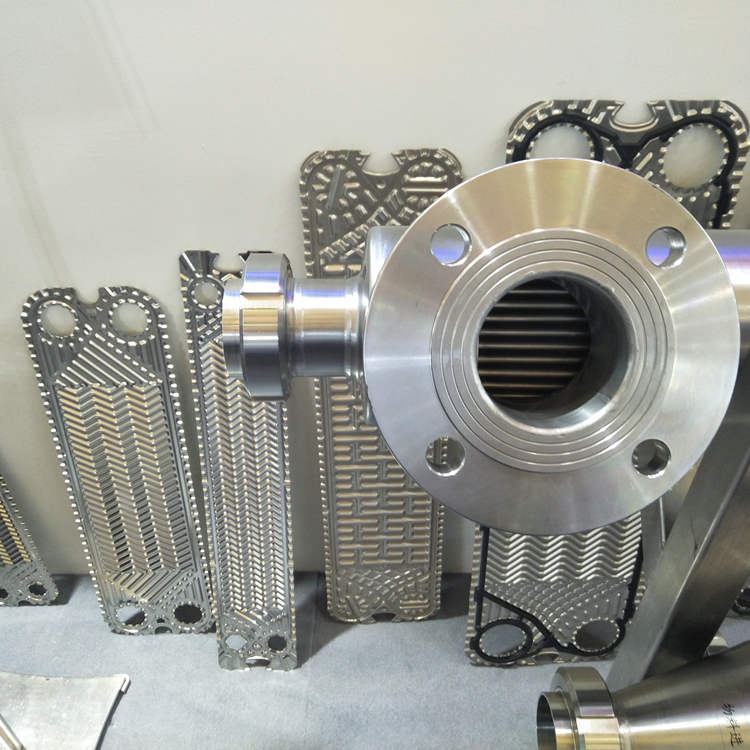

Heat exchanger | SUS304,Two stage cooling | |||

Wort oxygenator | SUS304, venturi principle with sight glass | |||

Yeast Adding Tank | 10L | With valve, sight glass, pipe fittings, hand-held | ||

Wort pump | China top brand, Sanitary SUS304 | |||

Hot liquid pump | China top brand, Sanitary SUS304 | |||

Pipe and fittings | As design | Completely SUS304,including platform and steps | ||

3 | Energy system | Steam heating | ||

4 | Fermentation system | Fermenter | 500L | Material:SUS316L /SUS304 |

Interior Shell: 2B/mirror plate; TH=3mm | ||||

80 mm PU for insulation | ||||

Dish head,cylinder,60 degree cone bottom(adjustable) | ||||

Top or side manhole, | ||||

With electromagnetic valve or mechanical pressure regulating valve,sample valve,temperature sensor, adjustable leg,Rotating | ||||

Option:Dry hop mouth,CO2 filling device With titanium | ||||

5 | Filtering system (optional) | Candle diatomaceous earth filtration | 500kg/hr | Power:1Kw |

Filter Area: 0.8M2 | ||||

SUS304 | ||||

6 | Fermentation system | Bright beer tank | 500L | Material:SUS316L or SUS304 |

Interior Shell: 2B/mirror plate; TH=3mm | ||||

80 mm PU for insulation | ||||

Dish head /bottom,cylinder | ||||

Top or side manway | ||||

With electromagnetic valve or mechanical pressure | ||||

7 | Cooling system | Chiller | 5Px1PCS | Cooling Capacity: 6364Kcal |

Installed Power:4.86kw | ||||

Refrigerant: R22 | ||||

Noise:70-80db | ||||

Coperland compressor | ||||

Ice Water Tank | 1500L | Insulated conical top and sloped bottom | ||

Ice water pump | 3M3 | Sanitary SUS304, VFD control | ||

Pipeline and fittings | As designed | SUS304 | ||

8 | Control system | Mashing and fermentation process Controlling | Floor type | Panel instrument digital |

PLC control with touch screen for special | ||||

9 | CIP System | Acid Tank | 50L | SUS304 |

Alkali Tank | 50L | SUS304 | ||

CIP Pump | 3M3 | Flow:3T Lift:24 | ||

10 | Filling system | Keg Washing machine | 40-60kegs/hr | Double Station Keg Rinser |

Heating: Electric, Power: 15kw(steam for optional) | ||||

Keg filling machine | 30-40kegs/hr | Single Station Keg Filler | ||

Input Power: 0.1 kw | ||||

Bottling line | 400-500 bottles/hr | Manual,8 heads | ||

Can line | ||||

11 | Option | Can be Customized | Malt-Silos | |

Malted tank | ||||

Auger system | ||||

Beer pasteurizer |

500L Brewpub Beer Brewing brewpub Systems product advantage

● WEMAC supply beer brewing system with turn-key project.

● WEMAC provide beer equipment with free consultation,3D design,free installation,training.

● Three years warranty for the main equipment and spare parts.

● WEMAC beer machine brew different flavors of beer and several flavors of beer at the same time.

● WEMAC beer machine has beautiful appearance, it is convenient for customer visiting.

500L Brewpub Beer Brewing brewpub Systems application scope

Absolutely, a 500L brewpub beer brewing system has a versatile application scope and can cater to various types of establishments within the craft beer industry. Here's a breakdown of the potential application areas for a 500L brewpub beer brewing system:

Small and Medium Breweries: A 500L brewpub system is ideal for small and medium-sized breweries that want to produce a diverse range of craft beers for their local market. It allows them to experiment with different recipes and offer a rotating selection of fresh and unique brews.

Regional Breweries: For regional breweries looking to expand their product line or experiment with new styles, a 500L brewpub system can serve as a pilot system for innovation and small-batch productions.

Bars and Pubs: Bars and pubs can enhance their offerings by brewing their own beer on-site. A 500L system enables them to have a signature house beer and potentially host events centered around their brewery.

Hotels and Resorts: Hotels and resorts with a 500L brewpub system can create a distinct beer experience for their guests. It adds an extra layer of entertainment and local flavor to their amenities.

Beer Houses and Taprooms: Beer houses and taprooms can utilize a 500L system to create a unique selling point, offering a selection of their own craft beers alongside other established brands.

Restaurants: Restaurants can use a 500L brewpub system to craft beer that complements their menu. It provides an opportunity for food and beer pairings and gives diners a one-of-a-kind experience.

Clubs and Entertainment Venues: Clubs and entertainment venues can elevate their offerings by brewing their own beer. A 500L system can help them stand out and attract a niche clientele.

Farm Breweries: Farm breweries can incorporate a 500L system to produce small batches of artisanal beer using ingredients grown on their own land, creating a strong connection to the local terroir.

Events and Festivals: A 500L brewpub system can be a great attraction at beer festivals, providing attendees with the opportunity to taste freshly brewed beers and interact with the brewing process.

Brewing Education Centers: Brewpubs with a 500L system can serve as educational centers, offering brewing classes and workshops for aspiring homebrewers and enthusiasts.

Collaborations and Special Releases: Brewpubs with a 500L system can collaborate with other breweries or businesses to create unique, limited-edition beers, driving interest and sales.

Community Engagement: Brewpubs with a smaller system can foster a strong sense of community engagement by inviting locals to participate in brewing events or even create their own beer recipes.

500L Brewpub Beer Brewing Systems basic information

Output capacity:500L(5HL)

Area request:25㎡

Building height requirement:2.5M

Power supply:Single Phase/ 220(110, 240…)v/50(60)Hz

3phase/380(220, 415,440…)v/50 (60)Hz

The internal and external surfaces of the equipment are polished, and the clamp is connected to the accessories to ensure that there are no thread dead ends.

The external lead wire is imported into the PLC control system. The temperature sensor has high temperature control accuracy and the error does not exceed 0.5 ℃. The PLC automatically controls the temperature and heating time.

WEMA

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- complete brewery for sale

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- hops addition gun

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- hop additive gun

- pilot brewing system

- Microbrewery machine

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

Best plate heat exchanger for beer brewery

The WEMAC plate heat exchanger (PHE) series is extensive, including multiple types of heat exchangers, suitable for all ...

More >>

500L Top quality craft beer brewery equipment

Double vessels craft beer brewing brewhouse for sale,mash/kettle tun + lauter/whirlpool tun are all made of high quality...

More >>

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Build me a 1500L beer brewery

mini beer brewery machine from 50L,which is suitable to use in home and family brewing,and micro beer brewery machine fr...

More >>

Best 500L beer brewing equipment suppliers near me

The nearest brewery system suppliers-WEMAC,we supply beer brewing system with turn-key project.

provide beer equipment ...

Best 500L beer brewhouse brewpub equipment

10hL steam heating Brewkit,most popular for the home brewing and small scale commercial brewery / brewpub.

Firstly,it c...

500L Steam heating beer brewery system Chinese suppliers ZXF

500L steam jacketed heating brewhouse,mash/kettle tun and lauter/whirlpool tun combination,PLC automaticlly control,suit...

More >>

beer brewing equipment manufacturers

Which is the best beer equipment manufacturer? How much investment does beer equipment need? What is included in the bee...

More >>