China professional craft beer brewing brewery factory expansion equipment mash tun and conical fermenters from WEMAC

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

WEMAC Craft beer brewing brewery factory expansionWEMAC beer brewing fermenters of beer brewery expaWEMAC mash tun of beer brewery expansionprofessional craft beer brewing equipment from WEM

Installing a Brewery Tips and Thoughts

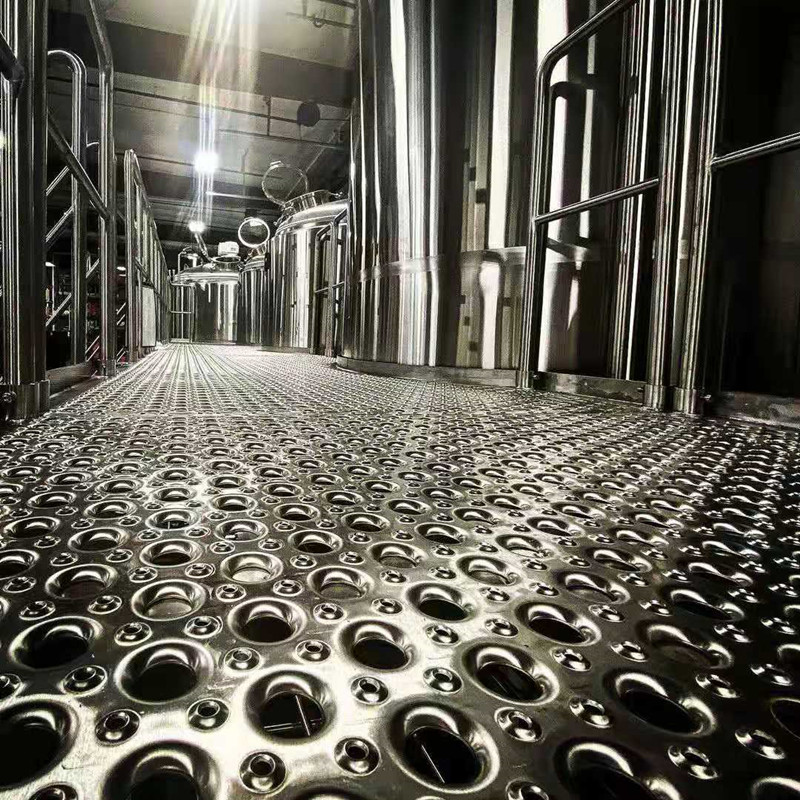

Their system couldn’t keep up with demand anymore and they knew that a larger brewery was the next step. Also, a bigger system allows them to open a few satellite bars in the city too.

Preparing for Your Brewery Install

Before the equipment arrived, we worked with the manufacturer and their engineers to plan the layout of the brewhouse. We provided them with the building floor plan then worked together on the layout of the brewery.

It’s important as it makes sure we have good work flows and that the utility ports (water and electric) were placed where needed in the building build out. As well as have the drains in the most useful positions.

Greater planning and preparation with your supplier agreed on before the equipment arrives will save time, money and heartache later on.

It makes the actual install more like putting together on giant jigsaw on site. As many of the connections and pipework have been pre-prepared by the manufacturer ready for delivery.

That’s where I refer back to the 7 P’s

Prior preparation and planning, prevents piss poor performance.

Installing a Brewery Tips – Wrap-Up

Anyway, this was just a short entry today just noting some of my thoughts about the installation for my client so far.

The installation has been a smooth one till now as we planned ahead using good communication as much as we could.

Good communication with your equipment manufacturer – always be open and honest with your manufacturer they can be extremely helpful with the buildout phase. They want the installation to be as much of a success as you. Open, honest and direct communication is the best.

Planning– Understand what you want your brewery to be and work with the manufacturer to make sure you get the right system to reach your brewing goals.

Be Prepared – Carrying out greater planning and groundwork before the equipment delivery; the quicker, cheaper and painless the install will be.

Send a Message

If you want to ask anything just fill in the form below and send us.

Name: Henrietta time:2020-11-25 10:53:31

The beer brewing equipments have been received, waiting for installation... everything goes well!

Name: Irving time:2020-11-19 10:47:15

Very professional craft beer brewing brewery factory expansion equipment. They sales very good.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- brewing equipment manufacturers uk,home brewing eq

- sovereign stainless steel fermenter

- Nano brewery equipment, brewing systems manufactur

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hops addition gun

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- Microbrewery machine

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

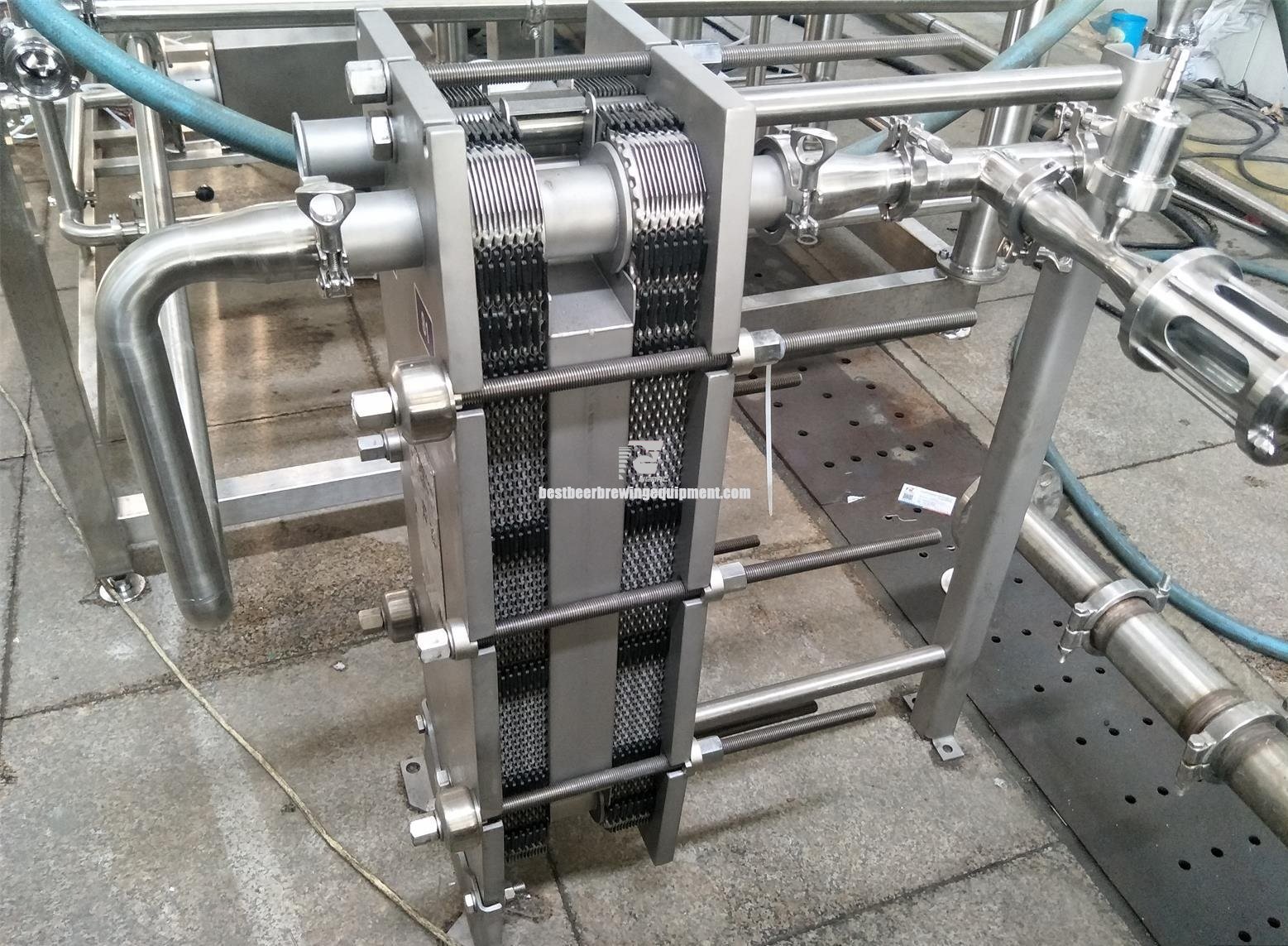

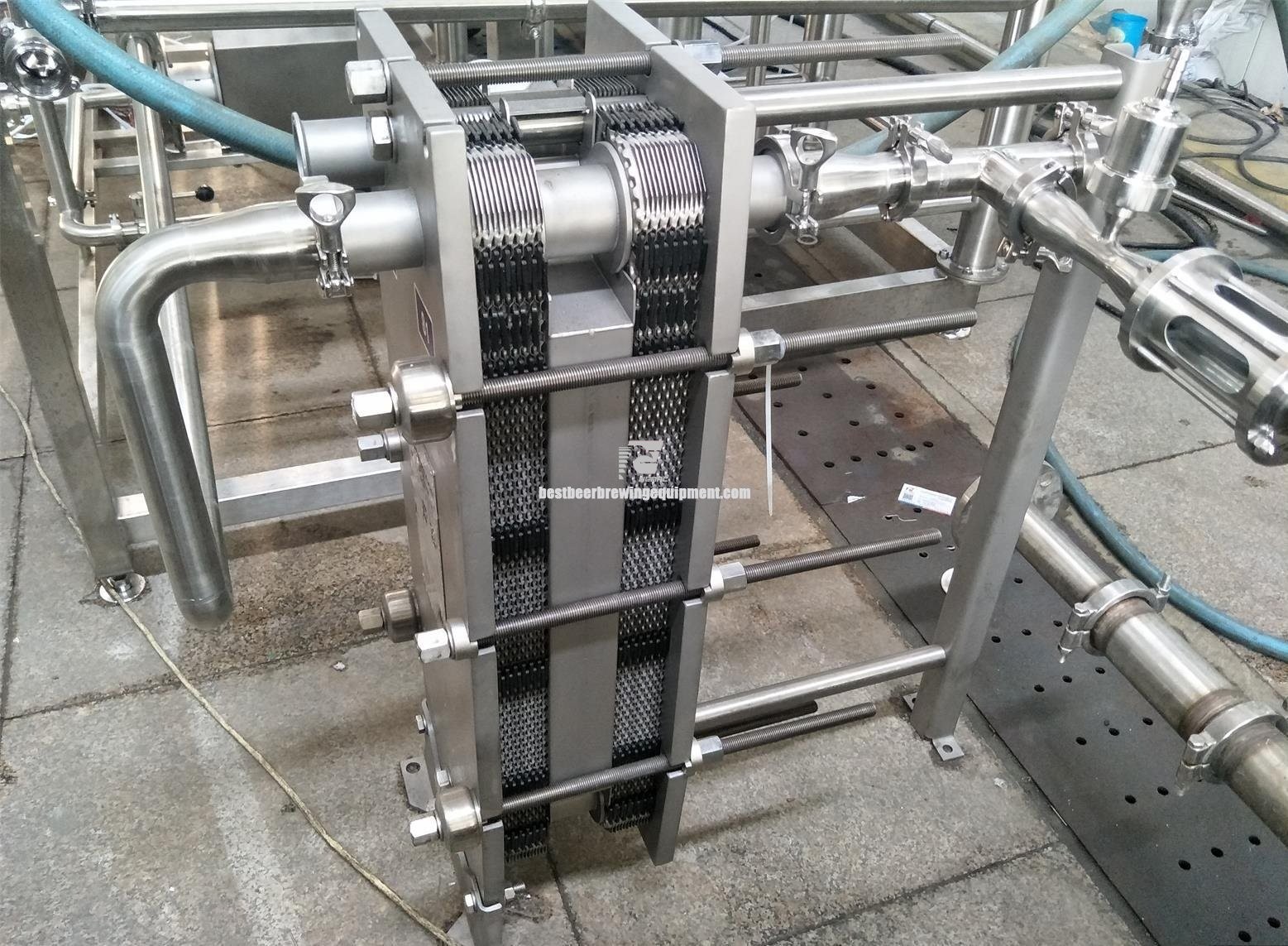

Best plate heat exchanger for beer brewery

The WEMAC plate heat exchanger (PHE) series is extensive, including multiple types of heat exchangers, suitable for all ...

More >>

500L Top quality craft beer brewery equipment

Double vessels craft beer brewing brewhouse for sale,mash/kettle tun + lauter/whirlpool tun are all made of high quality...

More >>

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Build me a 1500L beer brewery

mini beer brewery machine from 50L,which is suitable to use in home and family brewing,and micro beer brewery machine fr...

More >>

Best 500L beer brewing equipment suppliers near me

The nearest brewery system suppliers-WEMAC,we supply beer brewing system with turn-key project.

provide beer equipment ...

Best 500L beer brewhouse brewpub equipment

10hL steam heating Brewkit,most popular for the home brewing and small scale commercial brewery / brewpub.

Firstly,it c...

500L Steam heating beer brewery system Chinese suppliers ZXF

500L steam jacketed heating brewhouse,mash/kettle tun and lauter/whirlpool tun combination,PLC automaticlly control,suit...

More >>

beer brewing equipment manufacturers

Which is the best beer equipment manufacturer? How much investment does beer equipment need? What is included in the bee...

More >>