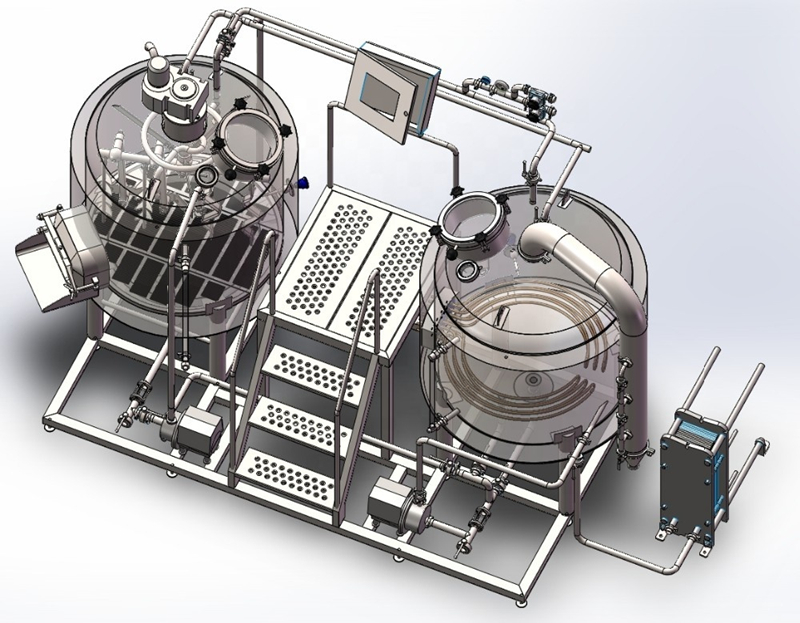

500L turnkey brewery equipment for sale china factory WEMAC G071

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

turnkey brewery equipment Complete microbrewery system Small microbrewery equipment Small brewery equipment price

Hops are a dioecious plant. The beer is produced using female hops, with a bitter content of 18.5%, hop oil 0.5%, polyphenols 3.5%, protein 20.0%, minerals 8.0% and others;

The bitterness of the bitter substance is high, which can improve the foam stability of the beer, so that the bitterness of the beer with higher bitterness is better;

The hop products mainly include granule hops, hop resin, hop oil, hop extract, etc.;

There are many varieties of hops, which are commercialized into fragrant hops and bitter hops;

Commonly used hop varieties are: Cascade Cascade, William M. Willamette, Czech Saaz Saaz, Qingdao, China.

The rankings of hops production in the world are: 39% in the United States (accounting for the world's total output), 34% in Germany, 7% in the Czech Republic, 6% in China, 2% in the UK, and the remaining 12%.

Water is the main raw material for beer production. The water consumption of beer production is very large. The water consumption per finished beer is between 3-10 hl and the average water consumption is 5-6 hl.

The brewing water must meet the drinking water quality requirements. The water treatment mainly includes the steps of removing suspended solids, removing dissolved matter, adjusting water hardness, desalting, sterilization and degassing.

Brewing water adjustment calculation: Calcium sulphate is required to add 120PPM of calcium ion in the feed liquid

The concentration of calcium ion in cold wort is above 50PPM, the concentration of calcium sulphate is >85%, and the gelatinization is slightly increased by a little more. The general calcium ion concentration is It can be around 20-30PPM. The calcium sulfate should be added to the filter water, such as a small part in the boiling pot.

Lactic acid (80%) adjusts the pH of mash to 5.4-5.6 (according to the wort after mashing, try to meet the pH value of 5.4-5.6 of mash, the final wort pH is 5.2-5.4, and the pH value is adjusted before boiling. .

Send a Message

If you want to ask anything just fill in the form below and send us.

Name: Isidore time:2020-05-15 16:10:36

Cooperated several times, very trustworthy brewery equipment manufacturer!

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- Nano brewery equipment, brewing systems manufactur

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hops addition gun

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- CIP system

- Microbrewery machine

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Turnkey brewing equipment supply near me

Turnkey brewing equipment supply-WEMAC can supply turnkey brewing equipment system.We are one of the most excellent turn...

More >>294.jpg)

All in one brewing system Australia

WEMAC beer equipment manufacturer is a well-known all in one brewing system, with more than 60 years of experience in th...

More >>

10HL 1000L Romania turnkey beer brewery equipment ZXF

1000L electric steam heating beer brewing brewhouse,sell well in Romania.Personalized customization, a variety of heatin...

More >>

Stainless steel boiling tank beer brewing brewery turnkey system supplier ZXF

All size brewery for sale,WEMAC Provide turnkey service for beer brewing system,Professional brewers and technical engin...

More >>

WEMAC 3000L Turnkey beer brewing brewery foul vessels brewhouse manufacturer ZXF

WEMAC specializes in undertaking large, medium and small beer brewing turnkey projects, the quality of WEMAC meets the G...

More >>

Modern beer making brewery turnkey brewhouse system made of high quality stainless steel ZXF

WEMAC provides a turnkey system for a modern beer brewing factory. From the storage and crushing of raw materials and ma...

More >>

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

Grain Handling

Heating System - Electric, Steam, or Direct Fire

Brew House Tanks

Brew House Controls

Pumps

Glycol &...