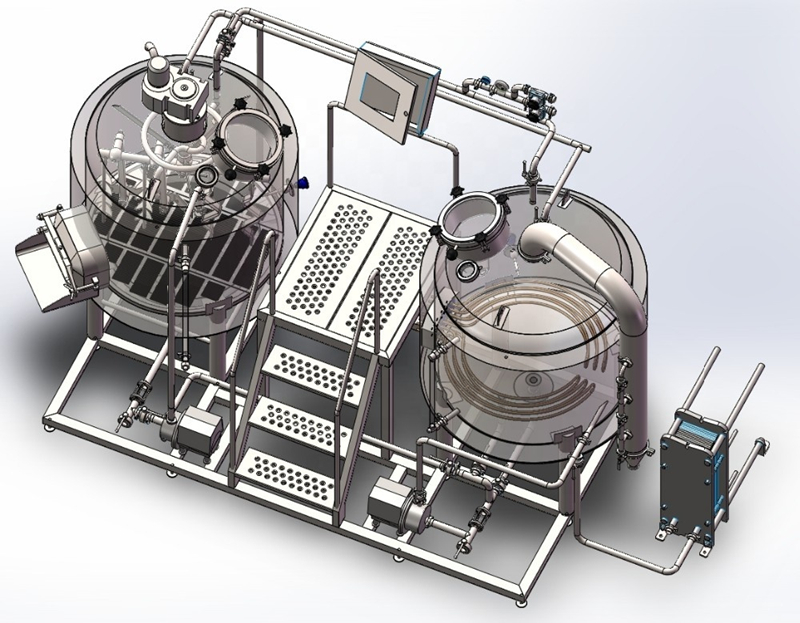

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

500L Beer plant Turnkey Brewing Systems300L Brewing Systems hot sale in Germany100L Turnkey beer brewing equipment

WEMAC provides various types of beer mash and fermentation systems. For beer brewing equipment, we are professional. Our 100L 300L 500L electric brewery turnkey brewing system is hot selling in Germany. In the heart of Europe, Germany has long been synonymous with beer craftsmanship and tradition. As the craft brewing industry continues to flourish in the land of beer, WEMAC's electric brewery turnkey systems are making waves and carving a niche for themselves. From 100L to 500L brewing capacity, our electric brewery systems have gained recognition for their innovation and precision. Brewing equipment can be divided into different types according to different heating methods. The common ones are gas steam heating, direct fire heating and electric heating. The following mainly talks about the characteristics of electric heating and related equipment production experience, hoping to provide guiding suggestions for the selection of equipment and the construction of the brewery.

Heating System

The source of heat is the heart of your brew house. Whether electric, steam, or direct/indirect fire is the best for your brewery depends on a range of factors. Your brew house size, the available utilities, and the initial and ongoing costs all need to be considered when deciding on a heat source.

Electric

Since 1958, we've been pioneers in brewing system. Our turnkey electric systems are available in up to 15 BBL brew houses with varying levels of automation to fit your style and budget. You might be used to brewing on a direct fire or steam system, but electric brewing has many advantages:

Electric heating is nearly 100% efficient. Because the heating element is submersed in the strike water or wort, all of the heat energy is transmitted directly to the liquid, not lost to heating your brewery

Electric heating enables a compact and flexible design, great for small spaces

Low equipment and installation costs

Precise control for a high level of repeatability and automation

No carbon emissions at the brewery

Steam

Steam systems are widely used for brewing systems of all sizes. We offer turnkey steam brew houses up to 30bbl with varying levels of automation. The steam systems have many advantages:

Go-to heat source for larger brew houses

Flexible design for tank placement

Higher efficiency (compared to direct fire)

Larger heating surface area than a direct fire system

Higher level of automation and repeatability than a direct fire system

Ideal for spaces with limited electrical power

Our turnkey systems include low-pressure boiler sized from 5 HP to 40 HP to meet your steam demands, and come with optional return/feed unit and blow down separator to provide a full steam solution.

Direct & Indirect Fire

A lot of brewers want a more traditional heat source, and Direct (up to 10 BBL) and Indirect Fire (up to 15 BBL) systems are a great choice. Ideal where the requirements for electric or steam hear are not available, and because they don't require a boiler, they come with a lower up-front equipment and installation cost compared to steam.

Why our electric brewery turnkey systems are so popular in Germany

A Tradition of Brewing Excellence

Germany's beer culture is rich and steeped in tradition, boasting a vast array of beer styles that have garnered worldwide acclaim. However, even in a land where centuries-old brewing practices are cherished, the need for innovation and efficiency is paramount. Microbreweries, craft brewers, and beer enthusiasts in Germany are embracing WEMAC's electric brewery turnkey systems to stay true to tradition while advancing the art of brewing.

Brewery Sizes to Suit All Needs

WEMAC's electric brewery turnkey systems come in a range of sizes, including 100L, 300L, and 500L. Whether you're a small microbrewery or a growing craft brewer, we have a solution tailored to your production needs.

Electric Efficiency

Electric brewing systems offer a high level of efficiency, and with Germany's commitment to sustainability and green energy, our electric systems align perfectly with the country's environmental goals.

Compact Design

Space efficiency is crucial for many German microbreweries. Our electric systems are designed to make the most of available space without sacrificing brewing capacity, making them an ideal fit for breweries with limited room to spare.

Precise Control

Brewing is an art that demands precision. Our electric systems offer precise temperature control and automation options that enable German brewers to maintain the consistency and quality that their customers expect.

Environmental Friendliness

In an era where sustainability is paramount, electric brewing stands out as an eco-friendly option. Our systems produce no carbon emissions at the brewery, contributing to a cleaner and more sustainable brewing industry in Germany.

Meeting Diverse Brewing Needs

The versatility of our electric brewery turnkey systems is a primary reason behind their success in Germany. Brewers in this country are known for their dedication to diverse beer styles, from traditional lagers to innovative craft brews. Our systems offer the flexibility to brew an array of beer types and experiment with new recipes, allowing German brewers to push the boundaries of brewing creativity.

Superior Craftsmanship

German brewers take pride in their attention to detail and unwavering commitment to quality. WEMAC shares this dedication and crafts each electric brewery system with precision and care. Every component is designed to meet the highest industry standards, ensuring that German brewers have reliable equipment that can produce exceptional beer for years to come.

Join the Brewing Revolution

As German beer culture continues to evolve and embrace innovation, WEMAC's electric brewery turnkey systems have found a strong foothold. We invite microbreweries, craft brewers, and beer enthusiasts in Germany to join the brewing revolution with our top-quality systems. Discover the perfect blend of tradition and innovation and be part of the legacy of brewing excellence in Germany. Contact us to learn more about our electric brewery systems and how they can elevate your brewing journey. Cheers to the future of German craft beer!

Contact us for a consultation as you start planning your brewery, and one of our Sales Systems Specialist will help you decide which heat source is right for you.

FAQ

1. What is a turnkey brewing system, and why is it "hot selling" in Germany?

A turnkey brewing system is a complete brewing setup that includes all the equipment needed for brewing, from mashing to fermentation. It's gaining popularity in Germany due to its efficiency, precision, and flexibility, making it an ideal choice for German brewers who are passionate about brewing quality beer.

2. What are the key features of WEMAC's electric brewery turnkey systems?

WEMAC's electric brewery turnkey systems come in different sizes (100L, 300L, and 500L) to cater to various brewing needs. They offer high efficiency, precise temperature control, compact design, and eco-friendliness, making them well-suited for the German brewing industry.

3. Why is electric efficiency important for breweries in Germany?

Electric efficiency is significant in Germany due to the country's focus on sustainability and green energy. Electric brewing systems align with Germany's commitment to eco-friendliness by producing no carbon emissions at the brewery.

4. Can WEMAC's electric brewery systems fit in small brewing spaces?

Yes, WEMAC's electric brewery systems are designed with a compact layout, making them ideal for breweries with limited space. This design ensures that breweries can maximize their brewing capacity without the need for extensive room.

5. How do these systems offer precise control for brewing?

WEMAC's electric systems provide precise temperature control, allowing German brewers to maintain consistent and high-quality brewing results. The automation options in these systems contribute to the repeatability and accuracy of the brewing process.

6. What types of beer can be brewed with these electric brewery systems in Germany?

The versatility of our electric systems enables German brewers to craft a wide range of beer styles, from traditional lagers to innovative craft brews. These systems are flexible and can accommodate diverse brewing needs.

7. How does WEMAC ensure the quality of its electric brewery turnkey systems?

WEMAC is committed to superior craftsmanship and designs each component to meet the highest industry standards. The systems are constructed with precision and care to provide reliable equipment for German brewers.

8. How can German breweries get in touch with WEMAC to learn more about these systems and make a purchase?

German breweries interested in our electric brewery turnkey systems can contact WEMAC through our website or get in touch with our sales team. We're here to provide information, answer questions, and guide you through the process of acquiring these systems for your brewery.

9. Are there any success stories or case studies of German breweries that have benefited from WEMAC's electric brewery systems?

Yes, we have several success stories and case studies showcasing how German breweries have benefited from our electric brewery systems. You can inquire about these examples when you contact us for more information.

10. What is the future of the brewing industry in Germany, and how do WEMAC's electric brewery systems fit into this landscape?

The brewing industry in Germany continues to evolve with a strong focus on innovation. WEMAC's electric brewery systems offer a perfect blend of tradition and modern brewing techniques, making them an ideal choice for German brewers looking to embrace the future of craft beer. These systems cater to the diverse and dynamic landscape of the German brewing industry, ensuring that quality and creativity remain at the forefront. Contact us to be a part of this brewing revolution in Germany.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- complete brewery for sale

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- hops addition gun

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- hop additive gun

- pilot brewing system

- Microbrewery machine

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Turnkey brewing equipment supply near me

Turnkey brewing equipment supply-WEMAC can supply turnkey brewing equipment system.We are one of the most excellent turn...

More >>294.jpg)

All in one brewing system Australia

WEMAC beer equipment manufacturer is a well-known all in one brewing system, with more than 60 years of experience in th...

More >>

10HL 1000L Romania turnkey beer brewery equipment ZXF

1000L electric steam heating beer brewing brewhouse,sell well in Romania.Personalized customization, a variety of heatin...

More >>

Stainless steel boiling tank beer brewing brewery turnkey system supplier ZXF

All size brewery for sale,WEMAC Provide turnkey service for beer brewing system,Professional brewers and technical engin...

More >>

WEMAC 3000L Turnkey beer brewing brewery foul vessels brewhouse manufacturer ZXF

WEMAC specializes in undertaking large, medium and small beer brewing turnkey projects, the quality of WEMAC meets the G...

More >>

Modern beer making brewery turnkey brewhouse system made of high quality stainless steel ZXF

WEMAC provides a turnkey system for a modern beer brewing factory. From the storage and crushing of raw materials and ma...

More >>

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

Grain Handling

Heating System - Electric, Steam, or Direct Fire

Brew House Tanks

Brew House Controls

Pumps

Glycol &...