Professional turnkey beer brewery equipment manufacturer widely acceped by beer factory--WEMAC

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

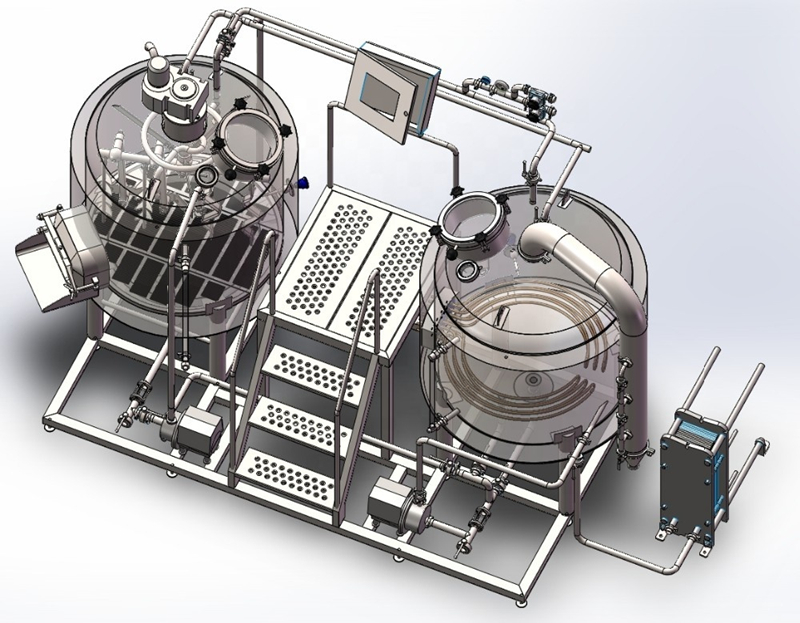

craft beer turnkey brewery equipmentturnkey beer brewing equipment an systemwidely used in big size beer brewing factoryprofessional beer brewing manufacturer WEMAC

WEMAC beer brewing services for the world

WEMAC takes the beer industry as its service object and integrates the advanced concepts of serving pharmaceutical into the entire beer industry. Beer equipment is a key development project of WEMAC, which specializes in the whole plant turnkey project dedicated to the design, R&D, manufacturing and engineering installation of beer systems. The company adheres to the goal of "professional solutions, high-quality manufacturing, and timely and perfect after-sales service" to provide customers with overall project solutions.

With the upgrading of domestic consumption and the implementation of new factory beer standards, small domestic craft brewing factories have emerged in China. This small craft brewing factory is very vital in a certain area. Based on the advantages that have been cultivated in pharmaceutical companies for many years, WEMAC leveraged on its own advantages, seized the rare market opportunities, rushed to catch up, and set off a new wave in the domestic beer market. The recent 10T mash system in Jinan, with an annual output of 30,000 tons, a turnkey project; Laiwu 10T mash system, with an annual output of 30,000 tons, a turnkey project; Qingdao 5T mash system, with an annual output of 10,000 tons, a turnkey project; Jinan 7.5T mash system, with an annual output of 2 Ten thousand tons of turnkey projects; Jiangsu 2.5T mash system, with an annual output of 5,000 tons of turnkey projects; have been delivered to customers, customers have been put into production, system operation problems, high degree of automation, has won unanimous praise from the industry. Many colleagues at home and abroad have visited these factories to learn from the experience of building a craft brewing factory, and visit high-level beer brewing equipment, whether it is the entire mash system, fermentation system, CIP system, cooling system, sterilization and filling system, the raw material processing system, the back-end packaging system, the entire control system, and the pipeline installation system are all first-class in the industry. Only first-class brewing equipment can produce first-class beer. This is the voice of many customers in the industry.

We provide customers with the following services:

Beer machine consultation

When you want to run a microbrewery or restaurant brewery, our engineer will provide professional consultation according to following factors:

1, Beer consumption

Before choosing beer equipment, please tell our sales manager beer consumption or sale quantity, the consumption of beer is seasonal, master the maximum daily consumption, monthly consumption to ensure continuous beer in the peak season.

2, Site conditions

Site conditions (water supply, drainage, electricity, ventilation, magnetic field, etc.) will effect the equipment. We suggest customer provide the site drawings and site surrounding environment to our engineer, if possible, ask for engineer to the site for having a look at first, WEMAC engineer will provide the appropriate solution according to the site conditions.

3, Estimated investment

Invest a microbrewery or bar, hotel, and not only equipment, also expects the late raw materials, water, electricity, and other administrative costs. Our staff will communicate with customer and do a cost-benefit analysis according to local equipment settlement price, consumption level in advance

4, Beer types

According to the region, the different taste preferences, customer hope get types of beer, it also effects equipment configuration, especially for the fermentation system.

5, Beer batches per day

Beer batch also effect equipment configuration, because the capacity of mashing and fermentation systems is multiple relation. For example, one batch beer brewing , mashing and fermentation capacity is the same. Two batch, fermentation capacity is double capacity of mashing system. But the biggest ratio cannot be more than three times. in accordance with the ordinary process, generally mashing time is 8 to 10 hours, a day and night can get 3 batches beer, 1 to 2 batches is best. In order to reduce the initial investment risk, cost savings, select multiple batches brewing equipment is a very good method

6, Beer technology

If customer have their own beer making process, please introduce to our engineer, our engineer will supply the reasonable configuration according to the brewing process.

7, A liquor equipment

There are variety of liquor equipment, price is different, customer will choose a suitable for themselves.

8, Equipment material

Stainless steel 304 is the common material for beer equipment. Stainless steel, carbon steel , copper is also used in beer production line. Our engineer will supply with professional consultation by customer requirement.

Beer brewing machine design

Our engineer will give customers professional advice and issue a plane or 3D layout to help customers more convenient more intuitive understand the expected effect more convenient &intuitive according to the customer site floor plan.

Beer system production

Beer making equipment tranportation

Brewery equipment installation

Send a Message

If you want to ask anything just fill in the form below and send us.

Name: Hosea time:2020-10-27 09:39:46

Good, Good, Good!

Name: Onions time:2020-10-20 13:31:05

Good quality, fast delivery and warm service. I really like this brewing equipment manufacturer so much.

Name: Harold time:2020-10-19 11:29:19

Good beer equipments, patience and meticulous service from the manufacturer.

Name: Galsworthy time:2020-10-12 10:14:20

This beer brewery equipment is much easier to use than my previous one. The quality is also good, it is thick and it should be durable. It must be praised!

Name: DeQuincey time:2020-10-10 09:43:15

This beer brewery equipment is high efficiency and energy saving, the appearance is atmospheric, the performance is higher than other similar products on the market, and the price is fair. I must give the manufacturer a positive evaluation!

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- brewing equipment manufacturers uk,home brewing eq

- sovereign stainless steel fermenter

- home brewing distillation equipment

- Nano brewery equipment, brewing systems manufactur

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hops addition gun

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- Microbrewery machine

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Turnkey brewing equipment supply near me

Turnkey brewing equipment supply-WEMAC can supply turnkey brewing equipment system.We are one of the most excellent turn...

More >>294.jpg)

All in one brewing system Australia

WEMAC beer equipment manufacturer is a well-known all in one brewing system, with more than 60 years of experience in th...

More >>

10HL 1000L Romania turnkey beer brewery equipment ZXF

1000L electric steam heating beer brewing brewhouse,sell well in Romania.Personalized customization, a variety of heatin...

More >>

Stainless steel boiling tank beer brewing brewery turnkey system supplier ZXF

All size brewery for sale,WEMAC Provide turnkey service for beer brewing system,Professional brewers and technical engin...

More >>

WEMAC 3000L Turnkey beer brewing brewery foul vessels brewhouse manufacturer ZXF

WEMAC specializes in undertaking large, medium and small beer brewing turnkey projects, the quality of WEMAC meets the G...

More >>

Modern beer making brewery turnkey brewhouse system made of high quality stainless steel ZXF

WEMAC provides a turnkey system for a modern beer brewing factory. From the storage and crushing of raw materials and ma...

More >>

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

Grain Handling

Heating System - Electric, Steam, or Direct Fire

Brew House Tanks

Brew House Controls

Pumps

Glycol &...