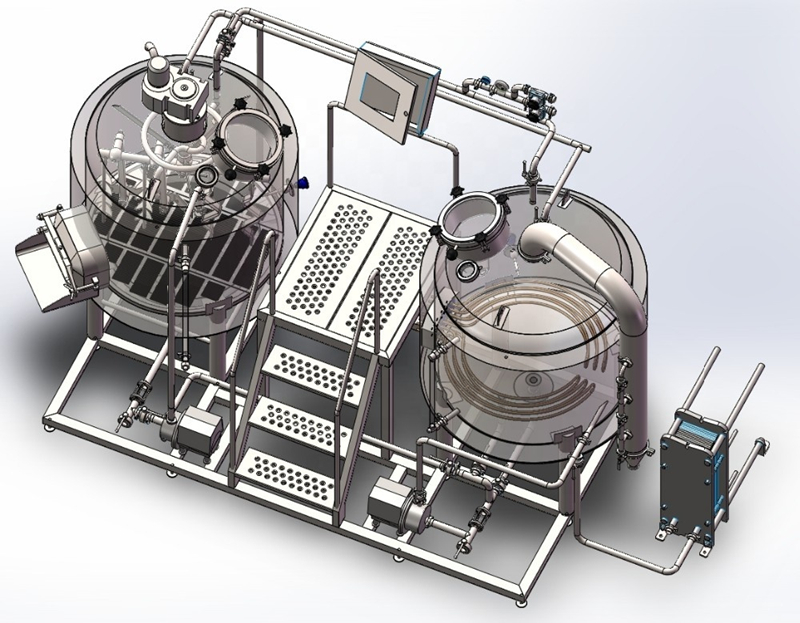

China stainless steel fermentation vessel conical beer fermenter WEMAC Y066

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

China stainless steel fermentation vessel conical beer fermenter WEMAC Y066

The included angle of the cone bottom is generally 60-80 °, and there are also 90-110 °,

but this is mostly used for large-capacity fermentation tanks.

The height of the cone bottom of the fermentation tank is related to the included angle.

The smaller the included angle is, the higher the cone bottom portion is.

Generally, the height of the cone bottom of the tank accounts for about 1/4 of the total height, and should not exceed 1/3.

The outer wall of the cone bottom should be provided with a cooling layer to cool the yeast deposited on the cone bottom.

The bottom of the cone should also be installed with inlet and outlet pipes, valves, sight glasses, temperature and pressure sensing elements.

In addition, the diameter to height ratio of the tank is usually 1: 2 to 1: 4, and the total height is preferably not more than 16m,

so as not to cause strong convection and affect the sedimentation of yeast and coagulum.

Cans can be made of stainless steel or carbon steel. If carbon steel is used,

the inner wall of the can must be coated with a non-toxic coating that does not affect the taste of beer.

The working pressure of the fermentation tank can be determined according to the working nature of the tank.

Generally, the working pressure of the fermentation tank is controlled between 0.2 and 0.3 MPa.

The inner wall of the tank must be smooth and flat, the inner wall of the stainless steel tank must be polished,

and the coating of the inner wall of the carbon steel tank must be uniform, with no uneven surface and no granular protrusions.

The fermentation broth in the tank produces a CO2 gradient (ie, a density gradient) due to the liquid height.

Through cooling control, natural convection of the fermentation broth can be achieved, and the higher the tank,

the stronger the convection. Due to the strong convection, the yeast's fermentation capacity is improved,

the fermentation speed is accelerated, and the fermentation cycle is shortened.

The top of the tank is a round arch structure. The central opening is used to place a detachable large-diameter flange

to install CO2 and CIP pipes and their connectors. The top of the tank is also equipped with sight glass, anti-vacuum valve,

overpressure valve and pressure sensor The tank is equipped with a washing device inside,

and a platform and a channel for tank top operation are also installed.

The fermentation tank should be equipped with a high-pressure spray washing device,

and the spray washing pressure should be controlled at 0.39 to 0.49 MPa or higher.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- home brewing distillation equipment

- Nano brewery equipment, brewing systems manufactur

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hops addition gun

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- Microbrewery machine

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Turnkey brewing equipment supply near me

Turnkey brewing equipment supply-WEMAC can supply turnkey brewing equipment system.We are one of the most excellent turn...

More >>294.jpg)

All in one brewing system Australia

WEMAC beer equipment manufacturer is a well-known all in one brewing system, with more than 60 years of experience in th...

More >>

10HL 1000L Romania turnkey beer brewery equipment ZXF

1000L electric steam heating beer brewing brewhouse,sell well in Romania.Personalized customization, a variety of heatin...

More >>

Stainless steel boiling tank beer brewing brewery turnkey system supplier ZXF

All size brewery for sale,WEMAC Provide turnkey service for beer brewing system,Professional brewers and technical engin...

More >>

WEMAC 3000L Turnkey beer brewing brewery foul vessels brewhouse manufacturer ZXF

WEMAC specializes in undertaking large, medium and small beer brewing turnkey projects, the quality of WEMAC meets the G...

More >>

Modern beer making brewery turnkey brewhouse system made of high quality stainless steel ZXF

WEMAC provides a turnkey system for a modern beer brewing factory. From the storage and crushing of raw materials and ma...

More >>

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

Grain Handling

Heating System - Electric, Steam, or Direct Fire

Brew House Tanks

Brew House Controls

Pumps

Glycol &...