500L 3BBL Commercial beer brewing brewhouse brewery bar system

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

3BBL beer brewing system500L beer brewhousebeer bar brewery systemcommercial beer brewing brewhouse system

In the dynamic world of craft brewing, the 500L 3BBL Commercial Beer Brewing Brewhouse emerges as a symbol of innovation and craftsmanship. This brewing system is tailored for brewery bars aiming to produce exceptional craft beer.

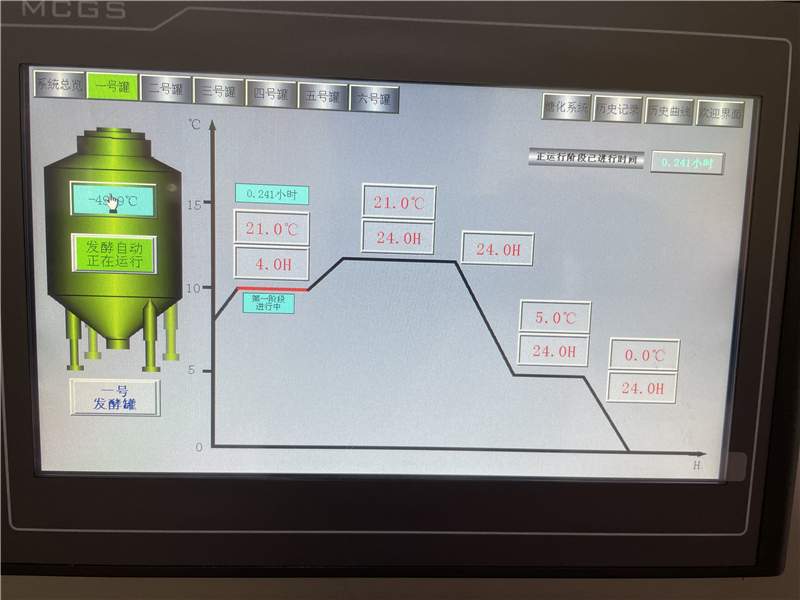

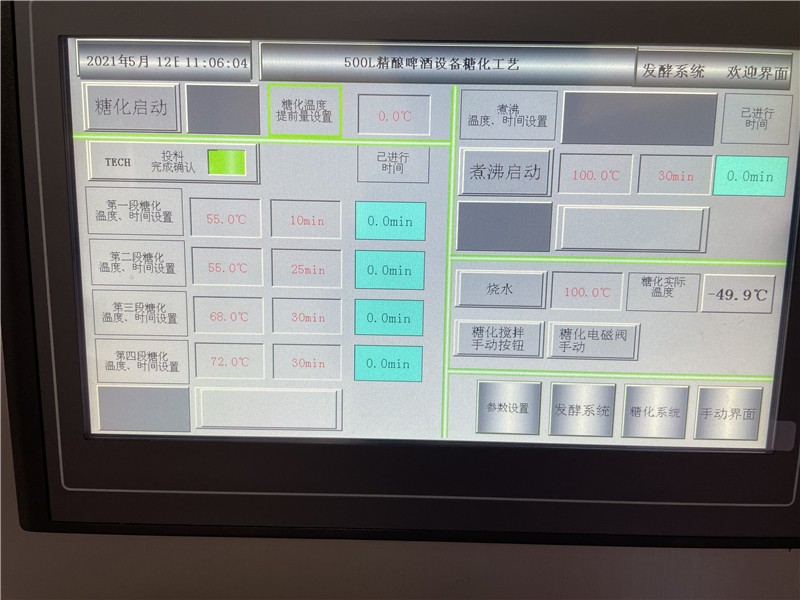

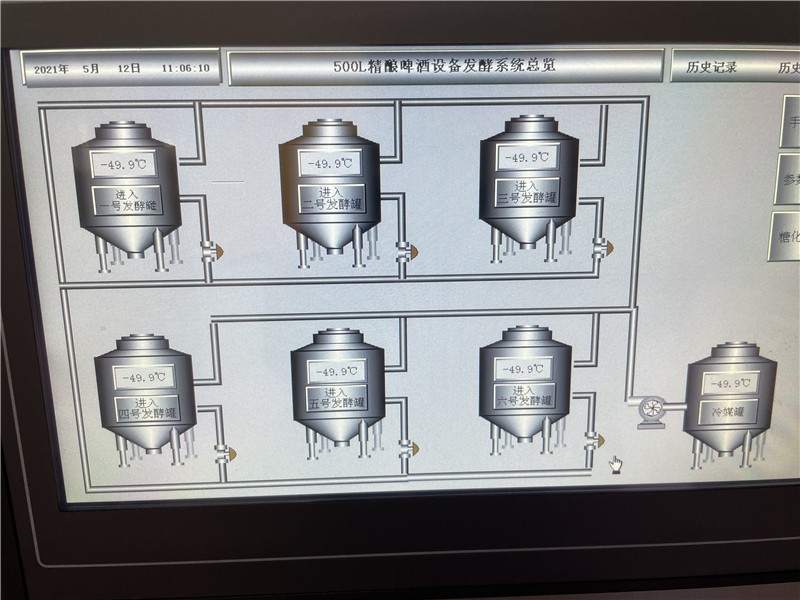

500L 3BBL beer brewing equipment, PLC control system interface, large touch screen control, automatic beer brewing,

With parameter settings, saccharification and fermentation, temperature control and temperature detection of the refrigeration system, users can independently set the temperature according to different types of beer. It is suitable for the production and brewing of stout, IPA, and other beers.

518861.jpg)

The interface control system adopts a temperature sensor, which has high temperature sensing accuracy, and the temperature difference of temperature control does not exceed 0.3°C. The electromagnetic valve is connected with the equipment and can control the open and close state online. Automatically control motor stirring.

The temperature and operating status of multiple fermentation tanks can be detected at the same time.

Jacketed fermentation tank, 80mm insulation layer, thermal insulation, pre-embedded with refrigeration cold water pipe, cold water is prepared by the refrigerator and stored in the cold water pipe, and the temperature is circulated and cooled in the fermentation tank through the cold water pump.

595037.jpg)

The fermentation history is traceable, and historical records and fermentation time curves can be queried.

500L 3BBL microbrewery brewhouse,two vessels unit,mash/kettle tun+lauter/whirlpool tun,this set of system is heated by gas steam,WEMAC provides steam/electric/direct fire virious kinds of heating method.

The top motor drives the inner stirrer and rotation in the tank, and the outside of the motor is equipped with a stainless steel protective cover, which improves the safety of operation and protects the motor.

When the stirring rake is turned forward, the grain is ploughed, and the grain is reversed. The forward and reverse rotations are automatically controlled by the PLC control system.

Top lauter tun,false bottom.the bottom is the whirlpool tun.The malt mixture after mash is pumped into it through a mash pump, which can be filtered naturally or by adding a compressor for suction filtration according to customer requirements.

Inner spray ball,the orifice is connected with CIP system,Effective spray cleaning is carried out on the tank, and there is no residue after cleaning. WEMAC offers CIP cart.

Advantages of 500L 3BBL Commercial beer brewing brewhouse for brewery bar system

The 500L 3BBL capacity strikes a perfect balance for brewery bars, allowing them to meet demand without sacrificing the quality of their craft beer. This intermediate size caters to establishments seeking a versatile brewing solution.

This brewhouse system offers a complete brewing solution, encompassing mash tuns, fermenters, and additional key components. The comprehensive nature of the system simplifies the brewing process for operators in brewery bars.

Crafted from premium stainless steel, the brewhouse system ensures durability, corrosion resistance, and a sanitary brewing environment. Stainless steel's properties contribute to the longevity of the equipment and the consistent production of high-quality craft beer.

The inclusion of conical fermenters is instrumental in improving the brewing process. The conical shape aids in sediment settling, resulting in clearer beer and minimizing undesirable flavors, enhancing the overall quality of the craft beer.

The brewhouse system is designed with brewery bars in mind, featuring a compact design that optimizes space efficiency. This is particularly beneficial for establishments with limited brewing space, ensuring a seamless integration into the bar environment.

Equipped with advanced temperature control systems, the 500L 3BBL Brewhouse ensures precise management of fermentation temperatures. This feature is crucial for achieving desired flavors and characteristics in the final brew.

Designed with a user-friendly interface, the brewhouse system simplifies the brewing process for operators. Intuitive controls and an easy-to-navigate system contribute to a seamless brewing experience in the dynamic setting of brewery bars.

The brewhouse system is scalable and flexible, allowing brewery bars to adapt to changing production needs. Whether experimenting with different beer styles or expanding production, this system accommodates the diverse requirements of brewery bars.

With a focus on energy efficiency, the brewhouse system minimizes waste and optimizes resource use. This not only benefits the environment but also contributes to cost savings for brewery bars.

The 500L 3BBL Commercial Beer Brewing Brewhouse stands as a testament to the commitment to excellence in craft brewing. Tailored for brewery bars, this brewing system empowers establishments to craft exceptional beer within the vibrant atmosphere of a bar setting. Cheers to the artistry and innovation of craft beer brewing in the heart of brewery bars!

WEMAC commercial beer brewing system can be customized according to customer needs. We have domestic professional equipment engineers to help customers plan from product design to flow chart and layout. The daily output ranges from 100L to 6000L. If you are interested in the distribution of brewing systems or the construction of beer craft brewing plants, we hope to help you expand your influence in the local market.

FAQ

Q1: What is the brewing capacity of the 500L 3BBL Commercial Beer Brewing Brewhouse?

A1: The brewhouse system has a brewing capacity of 500 liters (3BBL), making it ideal for brewery bars seeking a versatile brewing solution.

Q2: Can this system be customized for different beer styles?

A2: Yes, the 500L 3BBL Brewhouse system is designed for flexibility, allowing brewery bars to experiment with various beer styles and adapt to changing customer preferences.

Q3: How does the conical fermenter contribute to the brewing process?

A3: The conical fermenter's design aids in sediment settling, resulting in clearer beer and minimizing undesirable flavors. This enhances the overall quality of the craft beer produced.

Q4: Is the brewhouse system suitable for brewery bars with limited space?

A4: Yes, the system features a compact design optimized for brewery bars, ensuring efficient use of space and seamless integration into the bar environment.

Q5: What advanced temperature control features does the system offer?

A5: The brewhouse system is equipped with advanced temperature control systems, allowing precise management of fermentation temperatures for achieving desired flavors in the final brew.

Q6: How user-friendly is the interface for operators in a brewery bar setting?

A6: The system is designed with a user-friendly interface, featuring intuitive controls and an easy-to-navigate system. This simplifies the brewing process for operators in the dynamic setting of brewery bars.

Q7: Can the system accommodate an increase in production for brewery bars looking to expand?

A7: Yes, the brewhouse system is scalable and flexible, allowing brewery bars to adapt to changing production needs, whether experimenting with new beer styles or expanding their production capacity.

Q8: Does the stainless steel construction contribute to the quality of the beer produced?

A8: Absolutely, the use of premium stainless steel ensures durability, corrosion resistance, and a sanitary brewing environment. These properties contribute to the longevity of the equipment and the consistent production of high-quality craft beer.

Q9: How does the brewhouse system contribute to energy efficiency for brewery bars?

A9: The system is designed with a focus on energy efficiency, minimizing waste and optimizing resource use. This not only benefits the environment but also contributes to cost savings for brewery bars.

Q10: Can the brewhouse system be used by both new and established brewery bars?

A10: Yes, the 500L 3BBL Commercial Beer Brewing Brewhouse is suitable for both new and established brewery bars, offering scalability and adaptability to the diverse requirements of establishments at different stages of development.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- 15 gallon jacketed fermenter

- brewing equipment manufacturers uk,home brewing eq

- craft brewery equipment for sale, craft beer equip

- home brewing distillation equipment

- sovereign stainless steel fermenter

- complete brewery for sale

- automatically brew equipment,50L Brewing equipment

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- dry hops addition

- hop additive gun

- pilot brewing system

- hops addition gun

- Microbrewery machine

- Craft beer making equipment for Malaysia

- mixing tank manufacturers

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Commercial Beer Brewery Equipment

4000L four vessels craft beer brewing brewery system,gas steam heating,with a beer production of 12000L per day at least...

More >>

equipment needed to brew beer commercially

Equipment needed to brew beer commercially ,A beer brewing machine,Multiple flavors.Equipment needed to brew beer commer...

More >>

500L 3BBL Commercial beer brewing brewhouse brewery bar system

Two vessels craft beer brewing system,two vessels/three vessels/four vessels are optional.from 500L brewhouse to 5000L b...

More >>

China commercial 500L 3BBL 5BBL beer brewery brewhouse supplier manufacturer ZXF

WEMAC provides turnkey projects for beer brewing systems, large, medium and small beer brewing systems such as hotels, b...

More >>840.jpg)

WEMAC Commercial 1000L beer brewing equipment for sale south africa

Commercial 1000L beer brewing equipment for sale south africa Production capacity:10HL(1000L)

Heating method:steam heat...

Commercial 2 vessel and 3 vessel beer brewing equipment for sale brewery equipment list

We produce 2 vessel and 3 vessel brewing systems for commercial beer consumption places every year. Our professional eng...

More >>

China supplier commercial beer brewing equipment of Stainless steel to Morocco 2020 W1

We can produce commercial beer brewing equipment, we have factory from China. we can supply commercial beer equipment fo...

More >>

professional big size commercial beer brewing equipment hot sell in England Chinese supplier ZZ

the complete set of commercial beer brewing equipment including the following parts:Malt storage system,material handlin...

More >>