Turnkey beer brewing system uk

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

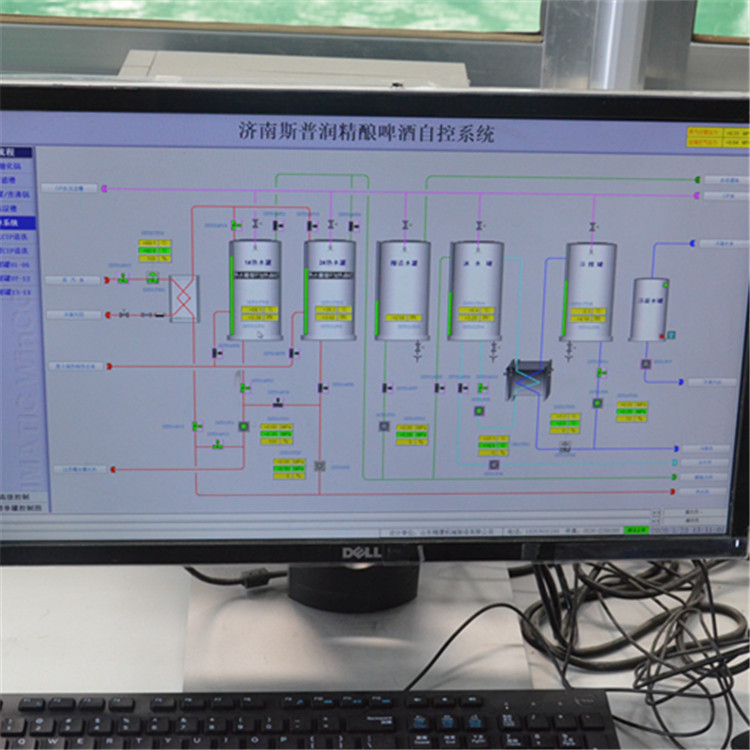

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

Complete beer brewing equipmenta set of brewery systemturkey brewery equipmentOne-stop beer equipment

The turnkey beer brewing system mainly considers two aspects, 1. The brewing process technical configuration requirements of the equipment. 2. The size and output requirements of the equipment. The output depends on the size of the saccharification equipment and the saccharification batches per day; and the size and number of fermentation tanks.

Best turnkey beer brewing system supplier

1. With decades of experience in the production of turnkey beer equipment, rich experience in planning, design, manufacturing, and installation.

2. Complete production equipment to ensure excellence in every process. Automated design: high degree of automation and labor saving.

3. The automatic temperature and pressure control is of high quality assurance, the equipment has a long service life, and the maintenance cost is low.

4. Have professional beer brewing engineers, beer equipment design engineers, and electrical engineers.

5. Maximize customer profit margins. Service advantages: beer equipment provides free project consultation, benefit analysis, plant graphic design, 3D renderings, hotel and production site graphic layout, equipment design, manufacturing, installation, commissioning, training, etc. The service implements a turnkey project.

Best turnkey beer brewing system

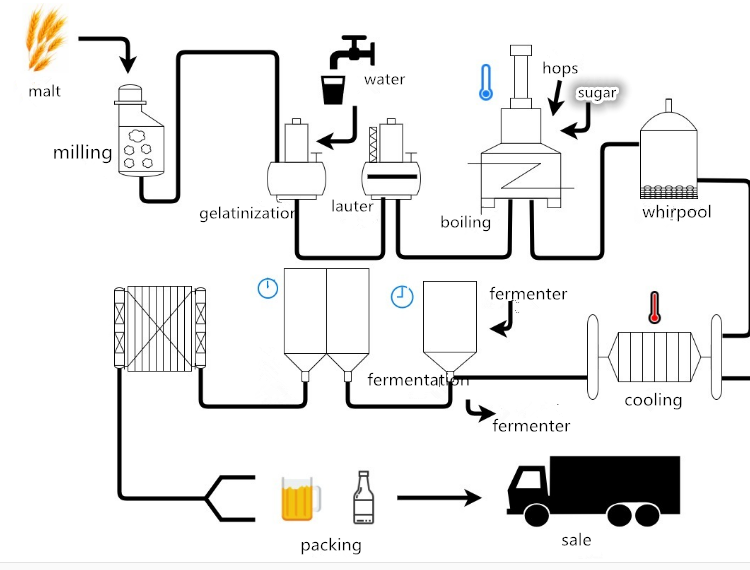

First of all, we should understand the process of beer brewing

Patameter of turnkey beer brewing system

| Items | WEMAC100L | WEMAC200L | WEMAC300L | WEMAC500L | WEMAC1000L | WEMAC2000L |

| Production capacity | 100L/D | 200L/D | 300L/D | 500L/D | 1000L/D | 2000L/D |

| Floor space | 15㎡ | 25㎡ | 35㎡ | 50㎡ | 80㎡ | 120㎡ |

| Ultimate capacity | 12kw | 12kw | 12/18kw | 15/45kw | 22/72kw | 31/144kw |

| Maximum hourly Water | 0.2m3/h | 0.4m³/h | 0.5m³/h | 1.0m³/h | 1.5m³/h | 2.0m³/h |

| Total water used | 0.5m3/d | 1m³/d | 1.5m³/d | 2.5m³/d | 5m³/d | 10m³/d |

| Consumption of malt | 20Kg | 40Kg | 60Kg | 100Kg | 200Kg | 400Kg |

| Consumption of hop | 60g | 120g | 180g | 300g | 600g | 1.2Kg |

| Yeast | 100g/1L | 200g/2L | 300g/3L | 500g/5L | 1Kg/10L | 2Kg/20L |

| Top steam | …… | 0.017t/h | 0.017t/h | 0.05t/h | 0.10t/h | 0.20t/h |

Turkey beer brewing system

Turkey beer brewing equipment is generally divided into: 1. Malt crushing system. 2. Mash system. 3. Fermentation bright beer system. 4. Energy system. 5. CIP cleaning system. 6. Control system, 7. Filling equipment, and other auxiliary systems.

Malt milling system of turkey brewery equipment

The crushing system is mainly composed of: malt crusher, malt storage and feeding equipment. Small equipment can only be equipped with a malt grinder. The crusher equipped for small and medium beer equipment is generally a pair of roller crushers, and large equipment is equipped with a four-roller or five-roller crusher. There are dry powder and wet powder for crushing. Small and medium-sized beer equipment is generally dry powder. Malt crushing is for better saccharification. The wheat husk is broken but not broken, and it is better to become a filter layer for wort filtration.

Mash system of turkey beer brewing equipment

| Model | Output | Combination mode | Voltage | Heating mode | Material | Scope of application | Control mode |

| 100L | 100L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | SUS304/316L | Hotel、wine bar.restaurant etc. | Semi automatic / automatic |

| Three vessels brewhouse | |||||||

| 200L | 200L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 500L | 500L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 1000L | 1000L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| Remark | The above models can be customized according to the requirements | ||||||

The mash system is the core of the whole set of equipment and is responsible for the process of making malt into wort. Namely: "mash-lauter-boiling-whirlpool" four main process steps; these four functional steps are completed by several tanks, called "mash with several devices". The hot water boiler is an auxiliary equipment.

Fermentation system of turkey brewery equipment

The fermentation system is composed of a fermentation tank. The fermentation tank has an inner tank, a cooling jacket, an insulation layer, and an outer skin, which have the functions of cooling and heat preservation.

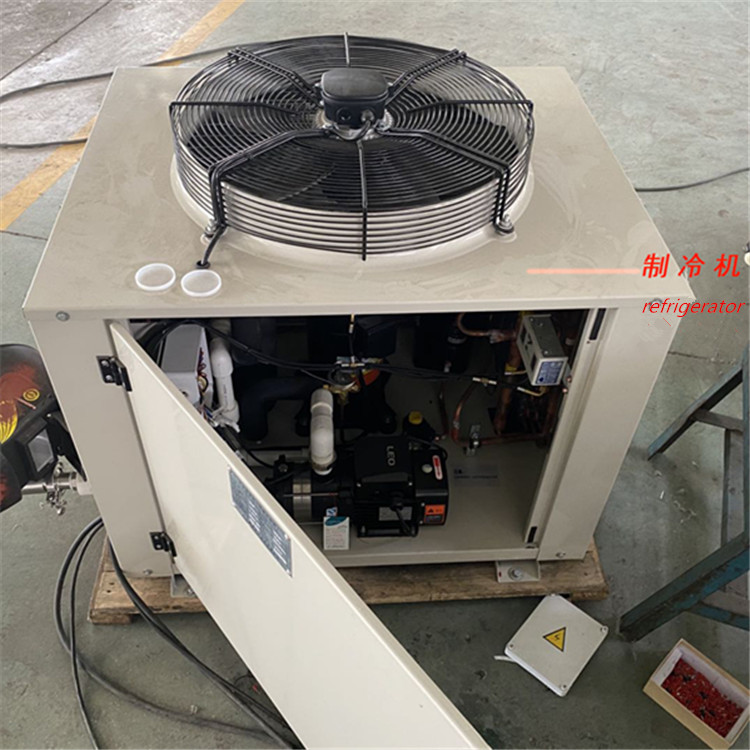

Cooling System of surkey beer brewing system

The main function of the refrigeration system is to provide a cold source for the cooling of the wort after the whirlpool and the cooling of the fermentation. The main equipment consists of: ice water tank (add 30% of the tank volume of ethylene glycol or edible alcohol to ensure that it does not freeze at minus 6°C), cold water tank (large equipment and multi-batch brewing need to be equipped, small equipment can not be used), Refrigerator composition.

FAQ

Q1: What is a turnkey beer brewing system?

A turnkey beer brewing system is a comprehensive and ready-to-use solution that includes all the essential components required for brewing beer. From the brewhouse equipment to fermentation tanks and control systems, a turnkey system streamlines the brewing process.

Q2: What are the benefits of a turnkey system?

Turnkey systems offer convenience and efficiency. They are designed to minimize the complexity of sourcing individual components and ensure compatibility between different parts of the brewing process. This allows brewers to focus on their craft and start brewing sooner.

Q3: What components are included in a turnkey brewing system?

A turnkey system typically includes a brewhouse (with mash/lauter tun, brew kettle, whirlpool), fermentation tanks, a glycol chilling system, control panels, piping, pumps, and more. Some systems may also include additional features like automated controls and recipe management.

Q4: What sizes are available for turnkey brewing systems?

Turnkey brewing systems come in various sizes to suit different production levels. Common sizes range from small pilot systems (1BBL) to larger commercial systems (20BBL or more). Choose a size that aligns with your production goals and available space.

Q5: Can I customize a turnkey system to my brewery's needs?

Yes, we offer customizable options for turnkey systems. You can often choose the number of fermentation tanks, control features, and other accessories based on your specific requirements.

Q6: What licenses and permits do I need in the UK to operate a brewery?

To operate a brewery in the UK, you'll need a Premises Licence under the Licensing Act 2003 and an Alcohol Wholesaler Registration Scheme (AWRS) registration if you plan to sell alcohol wholesale. You'll also need to comply with HM Revenue and Customs (HMRC) regulations.

Q7: How long does it take to set up a turnkey brewing system?

The timeline for setting up a turnkey system can vary depending on factors like the size of the system, any customization required, and the readiness of your brewery space. It's advisable to work closely with the supplier to determine a realistic timeline.

Q8: Can I receive training on how to use the turnkey system?

Yes, many turnkey system suppliers offer training as part of their package. Training can cover everything from equipment operation and maintenance to brewing techniques. Proper training ensures that you make the most of your investment.

Q9: What are the ongoing costs associated with a turnkey system?

Ongoing costs include ingredients, utilities (water, electricity, gas), maintenance, and possibly personnel if you hire staff. Calculating these costs and factoring them into your business plan is essential for sustainable brewery operations.

Q10: How can I ensure the quality of my beer using a turnkey system?

Quality control is crucial in brewing. With a turnkey system, it's important to maintain equipment cleanliness, follow best brewing practices, and conduct regular checks. Monitoring fermentation temperature, yeast health, and other parameters contributes to consistent quality.

Investing in a turnkey beer brewing system in the UK can be a pivotal step in realizing your brewing dreams. From reducing setup complexity to ensuring equipment compatibility, turnkey systems provide a comprehensive solution that allows you to focus on crafting exceptional beers. Cheers to your journey in the world of brewing!

If you plan to be a brewery or craft beer company, please contact us. Welcome to call or email for technical communication.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- brewing equipment manufacturers uk,home brewing eq

- sovereign stainless steel fermenter

- Nano brewery equipment, brewing systems manufactur

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hops addition gun

- hop additive gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- Microbrewery machine

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

Turnkey beer brewing system uk

The turnkey beer system program includes site planning, layout, equipment design, technical communication, installation ...

More >>

2500L Turnkey beer microbrewery brewhouse

2500L commercial beer brewery system turnkey project suppliers,the four vessels combination can brewing beer at least 4 ...

More >>

2 Vesssels Brewhouse equipment for beer brewing ZXF

Micro beer brewery system for people those new to beer brewing,one stop service from brewery design/manufacturing/traini...

More >>

1000L 7BBL Turnkey beer brewery brewing brewhouse system for sale ZXF

WEMAC offers flexible Brewhouse / Brew Kettle designs to ensure that optimal efficiency is achieved while including all ...

More >>

3BBL 5BBL turnkey beer microbrewery equipment manufacturer ZXF

steam heating 3BBL Craft beer brewing brewery,all made of high quality stainless steel,double wall heating tank,safe and...

More >>

Professional beer brewing system turnkey microbrewery equipment hot sell in Australia Chinese supplier ZZ

We can design suitable product technical solutions for customers according to customer needs. We are a leading domestic ...

More >>115.jpg)

SUS304 big size turnkey microbrewery beer brewing equipment widely used in brewing factory ZZ

WEMAC takes the beer industry as its service object and integrates the advanced concepts of serving pharmaceutical into ...

More >>

SUS304 Turnkey microbrewery equipment system for sale from Chinese factory Z1

Beer complete equipment refers to the beer complete equipment used in related beer production sites. The equipment is ma...

More >>