1000L brewing brite beer tank manufacturer WEMAC H011

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

In the pursuit of brewing excellence, quality equipment is paramount. WEMAC, as a professional beer brewing equipment manufacturer, proudly presents its 1000L Brewing Brite Beer Tank, crafted with precision and innovation to elevate your brewing operation. With a focus on quality, reliability, and performance, WEMAC empowers breweries to produce exceptional beers that delight the palate.

1000L brewing brite beer tank Introduction

Normally the bright tank’ structure is in cylinder shape with conical bottom. Some others are with ball shape bottom or in disc shape. Their main material is stainless steel, with PU or rock wool jacket for heat preservation. The temperature control is realized by the cooling media inside the jacket. It normally adjusts 2 stage or 3 stage cooling according to tank size and detailed request. Vertical bright tank is the most popular choice of many customers, from microbrewery equipment to big beer plant. It normally has the advantage of space saving. While horizontal bright tank is mostly applied for special working site structure, or just according to different customers’ interest.

Advantages of our 1000L brewing brite beer tank

The main structure of a brite tank includes tank top, tank body and tank bottom. Tank top is fixed with cleaning device, safety valve, feeding port and so on. All the devices and parts are of good quality and stable performance. Tank body is composed of inner tank, cooling jacket, heat preservation layer and outer tank. All parts are processed with professional and matured manufacturing. Tank bottom is equipped with discharge port and supporting legs. Most important, WEMAC tank material is solid and heavier than other factories’ product. This ensures WEMAC equipment is better in stability and lifetime.

WEMAC adopts scientific pressure preservation and cooling technique. The bright tank is equipped with high efficiency cooling jacket. It can fulfill fast cooling, multi stage cooling, parts cooling and other processing condition.

Perfect cleaning method and scientific tank body, top cover and bottom conical structure, ensures accurate supply of beer CO2, beer liquid cooling and tank cleaning process. The CIP, cooling water, temperature controlling system work together uniformly with highest efficiency.

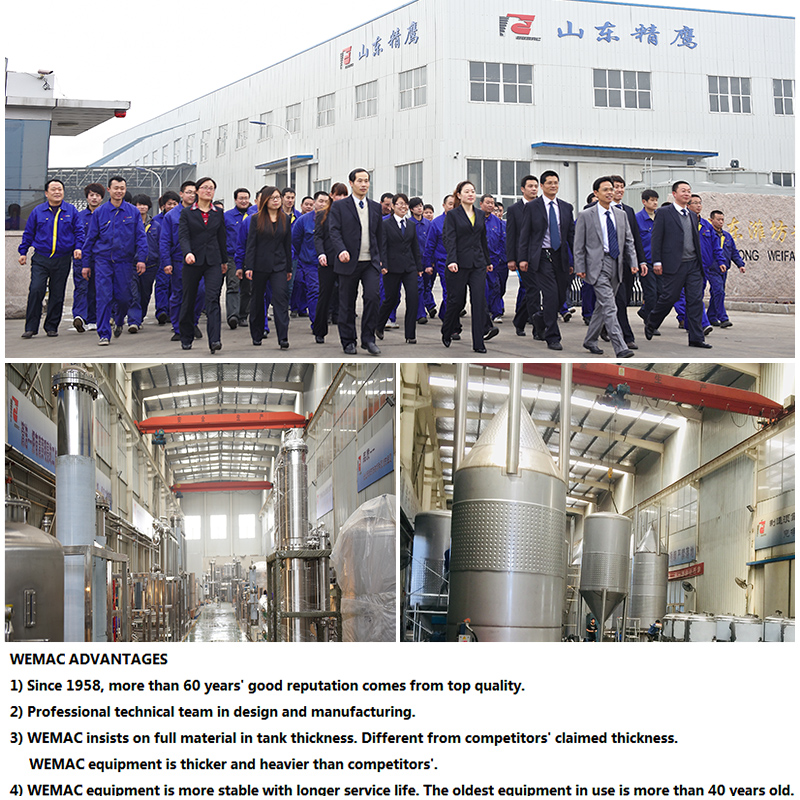

Advantages of WEMAC

WEMAC is a professional manufacturer based in China. WEMAC has an experienced sales and service team with professional equipment knowledge. There are about 2 customers visiting our factories per week in average. We attend national and domestic pharmacy equipment exhibitions and beer equipment exhibitions 2 times per month in average. All these face to face chances with customers, makes WEMAC team experienced and professional in equipment and customers’ usage. They know exactly what is the most suitable equipment for different customers, and can provide accurate and helpful solution and suggestion. Customers enjoy doing business with us.

Top quality manufacturing ability is our greatest advantage and constant principle since WEMAC establishment in 1958. Strict standard makes top quality manufacturing. Manufacturing ability is what makes us different. It also makes us industrial benchmark in domestic market. To make beer brewing equipment with pharma equipment quality makes WEMAC especially different from competitors.

WEMAC stainless steel material is also different. We insist on full and sufficient raw material. This is why our tank is always thicker, heavier and with longer service life than others’, no matter what they are claiming. We are strict on every set of equipment we make. We do not cut quality and material to offer a lower price, to get trouble for customers and for ourselves.

WEMAC is specialized in the production of high-quality 1000L brewing brite beer tanks. With a focus on precision engineering and innovative design, we are dedicated to providing breweries worldwide with reliable and efficient solutions for their brewing needs. Our 1000L brewing brite beer tanks are crafted with premium materials and advanced technology to ensure optimal performance, durability, and ease of use. Trust WEMAC to deliver excellence in brewing equipment and elevate your brewing operation to new heights.

FAQ

Q1: What is a 1000L brewing brite beer tank?

A: A 1000L brewing brite beer tank is a specialized vessel used in breweries to store and carbonate beer after fermentation. It is designed to maintain the beer's quality and clarity while also allowing for carbonation before packaging.

Q2: What are the key features of WEMAC's 1000L brewing brite beer tank?

A: WEMAC's 1000L brewing brite beer tank is equipped with features such as:

Stainless steel construction for durability and cleanliness

Insulated jacket for temperature control

Pressure relief valve for safety

Carbonation stone for efficient carbonation

Manway for easy access and cleaning

Q3: What is the capacity of WEMAC's 1000L brewing brite beer tank?

A: WEMAC's 1000L brewing brite beer tank has a capacity of 1000 liters, making it suitable for breweries producing medium to large batches of beer.

Q4: How is the beer transferred into and out of the 1000L brewing brite beer tank?

A: Beer is typically transferred into the tank from the fermentation vessel using a pump or gravity feed. It can then be carbonated and stored until it is ready for packaging, at which point it is transferred out of the tank using a similar method.

Q5: Can WEMAC customize the 1000L brewing brite beer tank to meet specific requirements?

A: Yes, WEMAC offers customization options for the 1000L brewing brite beer tank to accommodate specific brewery needs. This includes features such as additional ports, fittings, and accessories.

Q6: What support services does WEMAC provide for the 1000L brewing brite beer tank?

A: WEMAC provides comprehensive support services for the 1000L brewing brite beer tank, including installation assistance, operator training, maintenance, and technical support. Our team is dedicated to ensuring the smooth operation of your brewing equipment.

Q7: How can breweries inquire about or purchase WEMAC's 1000L brewing brite beer tank?

A: Breweries can inquire about or purchase WEMAC's 1000L brewing brite beer tank by contacting our sales team through our website, email, or phone. Our representatives will provide information on product options, customization possibilities, pricing, and ordering processes.

Send a Message

If you want to ask anything just fill in the form below and send us.

Name: Benson time:2019-11-07 09:24:49

Bright tank is made of high-quality stainless steel. Very stick. I am satisfied with it.

Name: Clifford time:2019-10-22 09:28:08

This 1000L brewing brite beer tank is good in quality &price. Very good seller.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- brewing equipment manufacturers uk,home brewing eq

- sovereign stainless steel fermenter

- Nano brewery equipment, brewing systems manufactur

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- beer brewing equipment

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- mixing tank manufacturers

- hop additive gun

- hops addition gun

- Craft beer making equipment for Malaysia

- pilot brewing system

- CIP system

- Microbrewery machine

- professional Cleaning in place equipment

FEATURED PRODUCTS

1000L brewing brite beer tank manufacturer WEMAC H011

Bright tank is also called brite tank. It is a professional storage tank for fresh beer. The tank is usually used in big...

More >>